Page 24 - MixStir® Chemical Delivery System

P. 24

MIXSTIR® CHEMICAL DELIVERY SYSTEM

Initial Startup

1) Contact your chemical supplier for information on the correct dilution ratio for the specific

chemical you will be using while considering the climate of your location. Dilution is adjusted

by changing the induction tip located on the HydroMinder assembly. See image below.

2) Adjust the bead chain length to position the float at the desired level of solution. The shorter

the chain the higher the liquid level will be when filling the MixStir®.

3) Insert chemical pick up tube into the raw chemical container (chemical drum).

Note: Be sure to read the manufacturer supplied “Operation and Safety Notes”

at the end of this section.

4) Slowly open the previously installed water ball valve. Water flow will start the siphoning of

chemical concentrate.

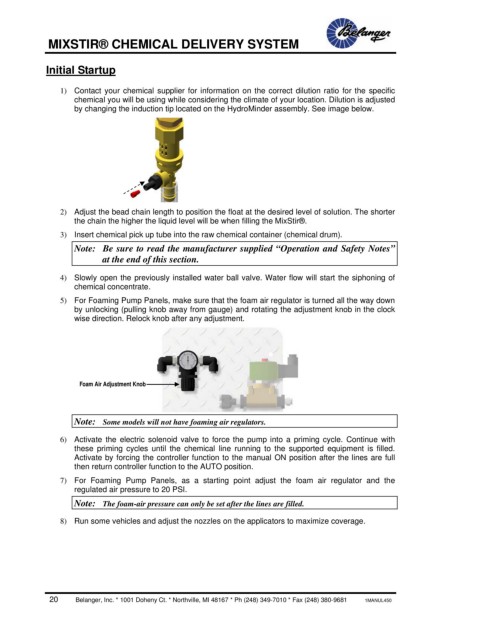

5) For Foaming Pump Panels, make sure that the foam air regulator is turned all the way down

by unlocking (pulling knob away from gauge) and rotating the adjustment knob in the clock

wise direction. Relock knob after any adjustment.

Foam Air Adjustment Knob

Note: Some models will not have foaming air regulators.

6) Activate the electric solenoid valve to force the pump into a priming cycle. Continue with

these priming cycles until the chemical line running to the supported equipment is filled.

Activate by forcing the controller function to the manual ON position after the lines are full

then return controller function to the AUTO position.

7) For Foaming Pump Panels, as a starting point adjust the foam air regulator and the

regulated air pressure to 20 PSI.

Note: The foam-air pressure can only be set after the lines are filled.

8) Run some vehicles and adjust the nozzles on the applicators to maximize coverage.

20 Belanger, Inc. * 1001 Doheny Ct. * Northville, MI 48167 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL450