Page 21 - MixStir® Chemical Delivery System

P. 21

MIXSTIR® CHEMICAL DELIVERY SYSTEM

Installation

Installing the MixStir®: for Systems

Before You Get Started

At this point the 3 MixSrir® tanks should be mounted and secured to the equipment room wall

with each chemical drum directly under its respective tank.

Vector® and Saber® Triple Foam Pods

1) From the 3-way divider that is on the primary air panel, run 3/8” polyflow tube to the inlet

side of the mini regulators that are on the secondary air panels.

2) Run field supplied 1/2” polyflow tube from the outlet of the Flojet pumps to the beginning of

the boom at the wall. Do this for all 3 pumps.

3) Locate the 3 supplied straight union reducers (1/2” x 3/8”) from the accessory box and

connect one to each end of the 1/2” polyflow tubes.

FreeStyler® Triple Foam Pods

1) From the 3-way divider that is on the primary air panel, run 3/8” polyflow tube to the inlet

side of the mini regulators that are on the secondary air panels.

2) Run field supplied 1/2” polyflow tube from the outlet of the Flojet pumps, through the boom,

and then connect them into the top three bulkheads that are on the bulkhead utility plate

weldment. The 1/2” lines coming from the other side of the bulkhead were installed at the

factory and are connected to the black triple foam manifold. Verify this at this time.

3) Once the three 1/2” polyflow lines are connected, you can proceed through the manual for

the main air and water hookups and to set the proper dilution ratio for your desired system.

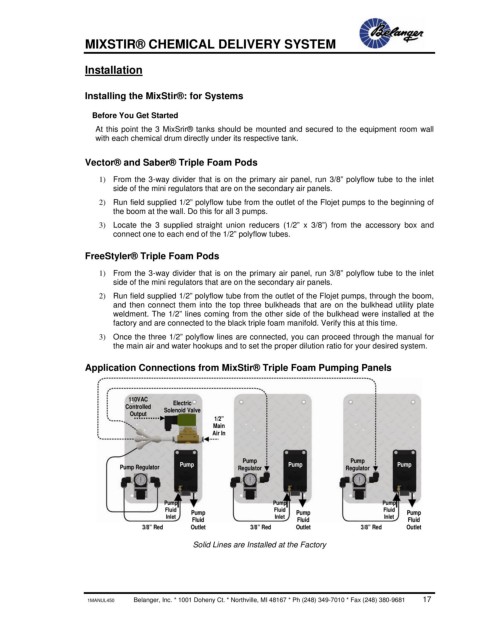

Application Connections from MixStir® Triple Foam Pumping Panels

110VAC Electric

Controlled

Output Solenoid Valve

1/2”

Main

Air In

Pump Pump

Pump Regulator Pump Regulator Pump Regulator Pump

Pump Pump Pump

Fluid Pump Fluid Pump Fluid Pump

Inlet Inlet Inlet

Fluid Fluid Fluid

3/8” Red Outlet 3/8” Red Outlet 3/8” Red Outlet

Solid Lines are Installed at the Factory

1MANUL450 Belanger, Inc. * 1001 Doheny Ct. * Northville, MI 48167 * Ph (248) 349-7010 * Fax (248) 380-9681 17