Page 1007 - Foton Workshop Manual - Auman EST-M

P. 1007

Frame, Suspension and Tire - Frame FR-7

Repair IN

1. Repair of rivet

DI

a. Remove the loose rivet head with a drill cut.

b. Thoroughly clear the two surfaces of the frame riveting parts.

EG

c. Determine the required rivet length and rivet diameter.

Caution

TR

Rivet hole wear due to loose rivet. When repairing the frame, the wear of old rivet hole should not

exceed the nominal size for 0.5mm, if the old rivet hole is larger than the nominal size for 0.5mm, the

hole can be enlarged for repair. AX

d. Remove the rust around the rivet hole.

e. Riveted with a pneumatic rivetter. FR

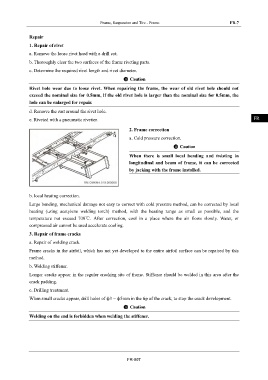

2. Frame correction

ST

a. Cold pressure correction.

Caution

BR

When there is small local bending and twisting in

longitudinal and beam of frame, it can be corrected

BW

by jacking with the frame installed.

EL

b. local heating correction.

Large bending, mechanical damage not easy to correct with cold pressure method, can be corrected by local

heating (using acetylene welding torch) method, with the heating range as small as possible, and the

temperature not exceed 700℃. After correction, cool in a place where the air flows slowly. Water, or

compressed air cannot be used accelerate cooling.

3. Repair of frame cracks

a. Repair of welding crack.

Frame cracks in the airfoil, which has not yet developed to the entire airfoil surface can be repaired by this

method.

b. Welding stiffener.

Longer cracks appear in the regular cracking site of frame. Stiffener should be welded in this area after the

crack padding.

c. Drilling treatment.

When small cracks appear, drill holes of ф3 ~ ф5mm in the tip of the crack, to stop the crack development.

Caution

Welding on the end is forbidden when welding the stiffener.

FR-007