Page 1519 - Foton Workshop Manual - Auman EST-M

P. 1519

Electrical system – electrical components EL - 95

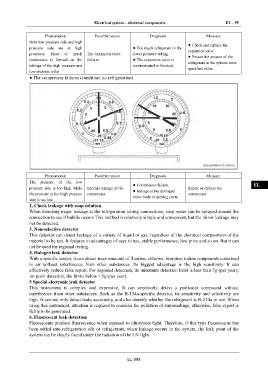

Phenomenon Possible reason Diagnosis Measure IN

Both low pressure side and high

● Check and replace the

pressure side are at high ● Too much refrigerant in the

expansion valve DI

pressures. Frost or much The expansion valve lower pressure tubing.

● Ensure the amount of the

condensate is formed on the failures ● The expansion valve is

refrigerant in the system meet

tubings of the high pressure and contaminated or blocked.

specified value. EG

low pressure sides

● The compressor failures (condition: no refrigeration)

TR

AX

FR

ST

BR

BW

Phenomenon Possible reason Diagnosis Measure

The pressure of the low

● Compressor failure. EL

pressure side is too high while Internal leakage of the Repair or replace the

● leakage at the damaged

the pressure of the high pressure compressor compressor

valve body or moving parts.

side is too low.

2. Check leakage with soap solution

When detecting major leakage at the refrigeration tubing connections, soap water can be sprayed around the

connection to see if bubble occurs This method is relatively simple and convenient, but the minor leakage may

not be detected.

3. Non-selective detector

This detector can detect leakage of a variety of liquid or gas, regardless of the chemical composition of the

material to be test. It features in advantages of easy to use, stable performance, low price and so on. But it can

not be used for regional testing.

4. Halogen leak detector

With a specific sensor, it can detect trace amounts of fluorine, chlorine, bromine, iodine compounds contained

in air without interference from other substances. Its biggest advantage is the high sensitivity. It can

effectively reduce false report. For regional detection, its minimum detection limit is less than 5g (per year);

for point detection, the limits below 1.5g (per year).

5 Special electronic leak detector

This instrument is complex and expensive, It can sensitively detect a particular compound without

interference from other substances. Such as the R-134a-specific detector, its sensitivity and selectivity are

high. It can not only detect leaks accurately, and also identify whether the refrigerant is R-134a or not. When

using this instrument, attention is required to consider the pollution of surroundings, otherwise, false report is

liable to be generated.

6. Fluorescent leak detection

Fluorescents produce fluorescence when exposed to ultraviolet light. Therefore, if this type fluorescents has

been added into refrigeration oils or refrigerants, when leakage occurs in the system, the leak point of the

system can be clearly found under the radiation of the UV light.

EL-095