Page 5 - POWERGEN E-Brochure

P. 5

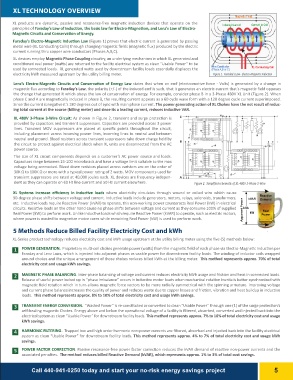

XL TECHNOLOGY OVERVIEW Magnetic Field

XL products are dynamic, passive and resonance-free magnetic induction devices that operate on the Induced Current Current in Coil

principles of Faraday’s Law of Induction, the basic law for Electro-Magnetism, and Lenz’s Law of Electro-

Magnetic Circuits and Conservation of Energy. Wire Conductor XL Conducting Coil

Faraday’s Electro-Magnetic Induction Law (Figure 1) proves that electric current is generated by passing (Phase A,B or C)

metal wire (XL Conducting Coils) through changing magnetic ?elds (magnetic ?ux) produced by the electric

current running thru copper wire conductors (Phases A,B,C). Figure 1. Faraday’s Law - Electro-Magnetic Induction

XL devices employ Magnetic Phase Coupling circuitry, an underlying mechanism in which XL generated and

conditioned real power (watts) are returned to the facility electrical system as clean “Usable Power” to be

used by connected loads. XL generated watts used by downstream facility loads essentially displaces the

electricity kWh measured upstream by the utility billing meter.

Lenz’s Electro-Magnetic Circuits and Conservation of Energy Law states that when an emf (electromotive force - Volts) is generated by a change in

magnetic ?ux according to Faraday's Law, the polarity (+/-) of the induced emf is such, that it generates an electric current that's magnetic ?eld opposes

the change that generated it which obeys the law of conservation of energy. For example, consider phase B in a 3-Phase 480V XL Unit (Figure 2). When

phase C and A are magnetically induced in phase B, the resulting current appears as a 60 cycle wave form with a 120 degree cycle current superimposed.

Since the current is negative it’s 180 degrees out of sync with main phase current. The power generating action of XL Chokes have the net result of reduc-

ing total current at the source (billing meter) and since its a leading current, reduces inductive VAR.

XL 480V 3-Phase 3-Wire Circuit: As shown in Figure 2, transient and surge protection is C

provided by capacitors and transient suppressors. Capacitors are provided across 3 power B

lines. Transient MOV suppressors are placed at speci?c points throughout the circuit,

including placement across incoming power lines, incoming lines to neutral and between A

neutral and ground. Bleed resistors across transient suppressors take down charge held by

the circuit to protect against electrical shock when XL units are disconnected from the AC Figure 2. Simpli?ed schematic of XL-480V 3-Phase 3-Wire

power source.

The size of XL circuit components depends on a customer’s AC power source and loads.

Capacitors range between 25-100 microfarads and have a voltage limit suitable to the max

voltage being connected. Bleed down resistors placed across varistors are on the order of

30K O to 100K O or more with a typical power rating of 2 watts. MOV components used for

transient suppressors are rated at 40,000 joules each. XL devices are frequency indepen-

dent as they can operate on 60 Hz line current and 50 Hz current elsewhere.

XL Systems increase e?ciency in inductive loads where electricity circulates through wound or coiled wire which cause Apparent Power Reactive

90-degree phase shifts between voltage and current. Inductive loads include generators, motors, relays, solenoids, transformers, kVAR Demand

etc. Inductive loads require Reactive Power (kVAR) to operate, this non-working power counteracts Real Power (kW) in electrical

circuits. Resistive loads on the other hand cause no phase shifts between voltage and current as they consume 100% of supplied kVA Real

Real Power (kW) to perform work. Unlike inductive loads which require Reactive Power (kVAR) to operate, such as electric motors, kW Power

where power is wasted to magnetize motor cores while remaining Real Power (kW) is used to perform work.

5 Methods Reduce Billed Facility Electricity Cost and kWh

XL-Series product technology reduces electricity cost and kWh usage upstream at the utility billing meter using the ?ve (5) methods below:

1 POWER GENERATION. Proprietary multi-coil chokes generate power (watts) from the magnetic ?eld of each phase via Electro-Magnetic Induction per

Faraday and Lenz Laws, which is injected into adjacent phases as usable power for downstream facility loads. The winding of inductor coils wrapped

around chokes and the unique arrangement of those chokes reduces billed kWh at the billing meter. This method represents approx. 70% of total

electricity cost and usage kWh savings.

2 MAGNETIC PHASE BALANCING. Inter-phase balancing of voltage and current reduces electricity kWh usage and friction and heat in connected loads.

Release of useful power locked up in “phase imbalance” occurs in inductive motor loads when mechanical rotation inertia is better synchronized with

magnetic ?eld rotation which in turn allows magnetic force vectors to be more radially symmetrical with the spinning armature. Improving voltage

and current phase balance increases the quality of power and reduces waste due to copper losses and friction, vibration and heat buildup in inductive

loads. This method represents approx. 8% to 10% of total electricity cost and usage kWh savings.

3 TRANSIENT ENERGY CONVERSION. ”Wasted Power” is re-constituted or converted to clean “Usable Power” through one (1) of the surge protection’s

self-healing magnetic Chokes. Energy above and below the operational voltage of a facility is ?ltered, absorbed, converted and injected back into the

electrical system as clean “Usable Power” for downstream facility loads. This method represents approx. 7% to 10% of total electricity cost and usage

kWh savings.

4 HARMONIC FILTERING. Trapped low and high order harmonic non-power currents are ?ltered, absorbed and injected back into the facility electrical

system as clean “Usable Power” for downstream facility loads. This method represents approx. 4% to 7% of total electricity cost and usage kWh

savings.

5 POWER FACTOR CORRECTION. Passive resonance-free power factor correction reduces the kVAR demand of reactive non-power currents and the

associated penalties. The method reduces billed Reactive Demand (kVAR), which represents approx. 1% to 3% of total cost savings.

Call 440-941-0250 today and start your no-risk energy savings project 5