Page 2187 - Flipbook_SolidDesignSoutheast2020

P. 2187

pneumatic conveying systems

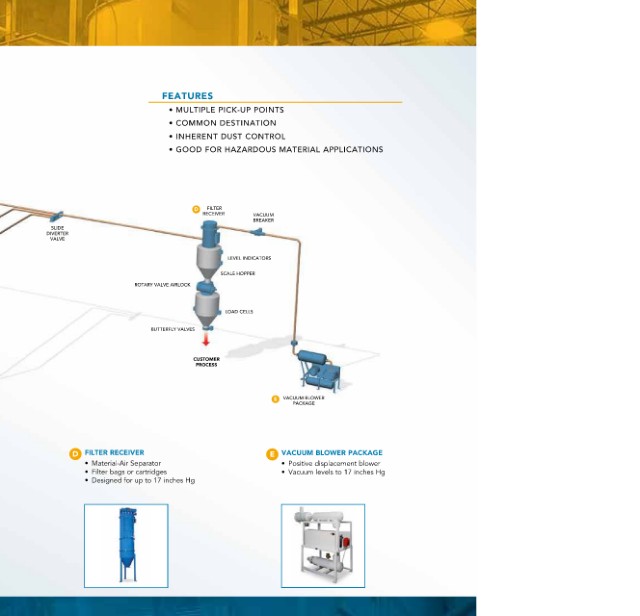

VACUUM SYSTEMS

DILUTE PHASE CONVEYING

FEATURES

BIN VENT • MULTIPLE PICK-UP POINTS

FILTER

BIN VENT

FILTER • COMMON DESTINATION

• INHERENT DUST CONTROL

• GOOD FOR HAZARDOUS MATERIAL APPLICATIONS

LEVEL

INDICATORS

STORAGE SILOS

D FILTER

RECEIVER VACUUM

BREAKER

INLET FILTER SLIDE

BIN ACTIVATOR DIVERTER

VALVE

KNIFE-GATE

VALVE

LEVEL INDICATORS

B ROTARY VALVE SCALE HOPPER

AIRLOCK

ROTARY VALVE AIRLOCK

HOIST AND TROLLEY

(OPTIONAL) LOAD CELLS

BUTTERFLY VALVES

A

BULK BAG

UNLOADING STATION INLET FILTER

CUSTOMER

PROCESS

INLET FILTER

C BAG DUMP WITH E VACUUM BLOWER

INTEGRAL FILTER

PACKAGE

A BULK BAG UNLOADING B ROTARY VALVE AIRLOCK C BAG DUMP HOPPER D FILTER RECEIVER E VACUUM BLOWER PACKAGE

• 100 lb to 4000 lb capacity • Available in various sizes and materials • Allows manual introduction • Material-Air Separator • Positive displacement blower

• Compact footprint • Controls material feed into convey line of material to system • Filter bags or cartridges • Vacuum levels to 17 inches Hg

• Manages pressure differential between • Designed for up to 17 inches Hg

convey line and feed source