Page 2192 - Flipbook_SolidDesignSoutheast2020

P. 2192

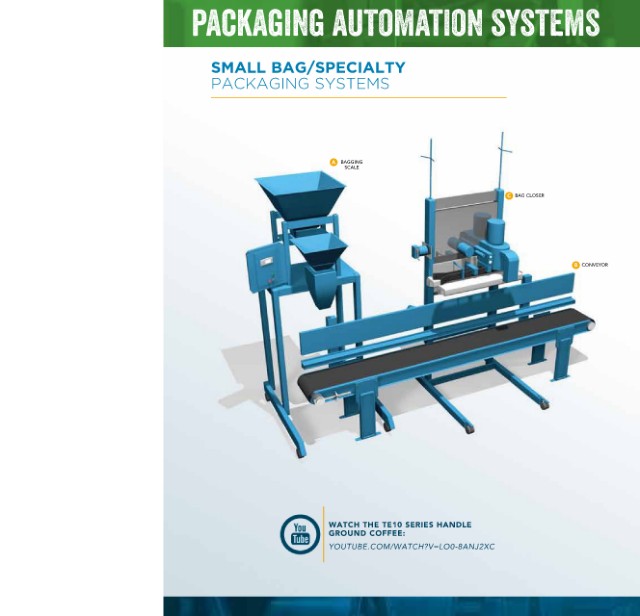

packaging automation systems

SMALL BAG/SPECIALTY

PACKAGING SYSTEMS

FEATURES

+ SEMI-AUTOMATED AND FULLY-AUTOMATED OPTIONS

+ HANDLE POWDERS PELLETS, FLAKES, AND CHIPS

A BAGGING + SIMPLEX AND DUPLEX CONFIGURATIONS

SCALE

+ UP TO 1,440 BAGS PER HOUR WITH DUPLEX MODELS

C BAG CLOSER

A BAGGING SCALE B BAG CLOSING CONVEYOR

TE-10C TSC

B CONVEYOR • Fill 2 oz - 5 lb bags, Up to 12 BPM • Flat Belt or V-Belt Option

• Vibratory Feeder - Net Weigh Bucket • Bag Guides

• Conical Hopper increases material flow • Foot Pedal

• Tool-less disassembly for ease of clean-up

• Stainless steel construction

C BAG CLOSER

400 NS™ - SEWER

• “Plain” Sewing System

TE-10/TE-10JUMBO • Multi-wall paper bags, woven,

• Up to 12 BPM and laminated polypropylene

• Vibratory Feeder with Net Weigh • Automatic In-feed

Bucket • Adjustable Height/Mobile Frame

• Integral Product Hopper

• Weigh Controller HOT AIR SEALER

• Pillow Type Bag Sealer

• Speed 0-60 fpm

• Bag Top Trimmer

• Fwd/Off/Rev Switch

TE-10 DUPLEX/ JUMBO DUPLEX

• Up to 24 BPM BAND SEALER

• Dual Vibratory Feeders with Net Weigh • Heat Seal

Bucket • Flat Belt

• Feed two products

• Integral Product Hopper

• Weigh Controller

WATCH THE TE10 SERIES HANDLE

GROUND COFFEE:

YOUTUBE.COM/WATCH?V=LO0-8ANJ2XC