Page 2188 - Flipbook_SolidDesignSoutheast2020

P. 2188

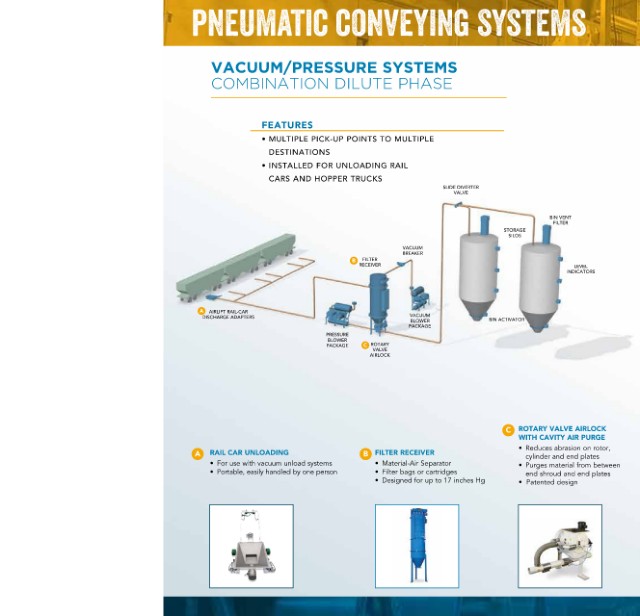

pneumatic conveying systems

VACUUM/PRESSURE SYSTEMS ECO PHASE PNEUMATIC

COMBINATION DILUTE PHASE CONVEYING SYSTEMS

FEATURES FEATURES

• MULTIPLE PICK-UP POINTS TO MULTIPLE • REDUCED ENERGY CONSUMPTION

DESTINATIONS • MAXIMIZES THE BEST ATTRIBUTES OF DILUTE

• INSTALLED FOR UNLOADING RAIL AND DENSE PHASE CONVEYING

CARS AND HOPPER TRUCKS • CONSTANT DELIVERY OF MATERIAL

SLIDE DIVERTER

VALVE BIN VENT

FILTER

SLIDE BIN VENT

BIN VENT DIVERTER FILTER

FILTER VALVE

FILTER

STORAGE F BIN VENT

SILOS

VACUUM

BREAKER

B FILTER

RECEIVER LEVEL PRESSURE

INDICATORS E BLOWER

PACKAGE

A AIRLIFT RAIL-CAR

DISCHARGE ADAPTERS VACUUM BIN ACTIVATOR

BLOWER

PACKAGE TRUCK FILL LINE

PRESSURE MAGVEYOR ROTARY

VALVE

BLOWER D ECO-PHASE AIRLOCK

PACKAGE C ROTARY TRANSMITTER

VALVE

AIRLOCK

STORAGE SILO CUSTOMER

PROCESS

C ROTARY VALVE AIRLOCK D MAGVEYOR

WITH CAVITY AIR PURGE • Unique technology

• Reduces abrasion on rotor, • Patented

A RAIL CAR UNLOADING B FILTER RECEIVER cylinder and end plates • Continuous Feed E PRESSURE BLOWER PACKAGE F BIN VENT

• For use with vacuum unload systems • Material-Air Separator • Purges material from between • No ASME Code vessel required • Positive displacement blower • Material-air separator

• Portable, easily handled by one person • Filter bags or cartridges end shroud and end plates • High Solids loadings • Pressures to 15 psig • Pulse jet filter

• Designed for up to 17 inches Hg • Patented design • Lower Velocities • Up to 15 Hg

• Minimal material degradation