Page 5 - File 1

P. 5

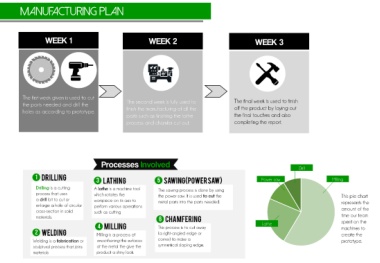

Manufacturing plan

WEEK 1 WEEK 2 WEEK 3

The first week given is used to cut The final week is used to finish

the parts needed and drill the The second week is fully used to off the product by laying out

holes as according to prototype. finish the manufacturing of all the

parts such as finishing the lathe the final touches and also

process and chamfer cut out. completing the report.

Processes Involved Drill

drilling lathing Sawing(power saw) Power saw Milling

Drilling is a cutting A lathe is a machine tool The sawing process is done by using

process that uses which rotates the the power saw. It is used to cut the This pie chart

a drill bit to cut or workpiece on its axis to metal parts into the parts needed. represents the

enlarge a hole of circular perform various operations

cross-section in solid such as cutting amount of the

materials. Chamfering time our team

spent on the

milling This process is to cut away Lathe machines to

welding Milling is a process of (a right-angled edge or create the

Welding is a fabrication or smoothening the surfaces corner) to make a prototype.

sculptural process that joins of the metal the give the symmetrical sloping edge.

materials product a shiny look.