Page 7 - File 1

P. 7

Manufacturing plan

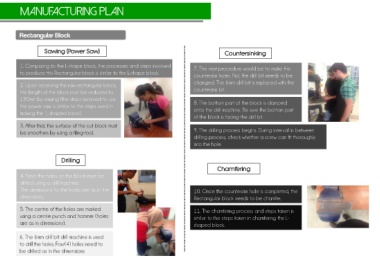

Rectangular Block

Sawing (Power Saw) Countersinking

1. Comparing to the L-shape block, the processes and steps involved 7. The next procedure would be to make the

to produce this Rectangular block is similar to the L-shape block.

countersink holes. First, the drill bit needs to be

changed. The 6mm drill bit is replaced with the

2. Upon receiving the raw rectangular block,

the length of the block must be reduced to countersink bit.

190mm by sawing (the steps involved to use

the power saw is similar to the steps used in 8. The bottom part of the block is clamped

onto the drill machine. Be sure the bottom part

making the L-shaped block).

of the block is facing the drill bit.

3. After that, the surface of the cut block must

be smoothen by using a filing tool. 9. The drilling process begins. During interval in between

drilling process, check whether a screw can fit thoroughly

into the hole.

Drilling

Chamfering

4. Next, the holes on the block must be

drilled using a drill machine.

The dimensions for the holes are as in the 10. Once the countersink hole is completed, the

dimensions. Rectangular block needs to be chamfer.

5. The centre of the holes are marked 11. The chamfering process and steps taken is

using a centre punch and hammer (holes similar to the steps taken in chamfering the L-

are as in dimensions). shaped block.

6. The 6mm drill bit drill machine is used

to drill the holes. Four(4) holes need to

be drilled as in the dimensions