Page 6 - File 1

P. 6

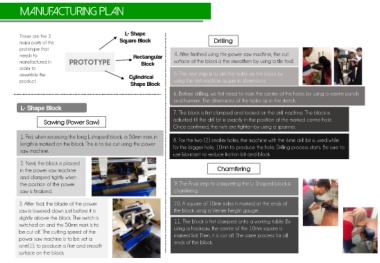

Manufacturing plan

L- Shape

These are the 3

major parts of the Square Block Drilling

prototype that

needs to Rectangular 4. After finished using the power saw machine, the cut

manufactured in Block surface of the block is the smoothen by using a file tool.

order to

assemble the Cylindrical 5. The next step is to drill the holes on the block by

product. using the drill machine as per in dimensions.

Shape Block

6. Before drilling, we first need to mark the centre of the holes by using a centre punch

and hammer. The dimensions of the holes as in the sketch.

L- Shape Block

7. The block is first clamped and locked on the drill machine. The block is

Sawing (Power Saw) adjusted till the drill bit is exactly in the position of the marked centre hole.

Once confirmed, the nuts are tighten by using a spanner.

1. First, when receiving the long L-shaped block, a 50mm mark in 8. For the two (2) smaller holes, the machine with the 6mm drill bit is used while

length is marked on the block. The is to be cut using the power for the bigger hole, 10mm to produce the hole. Drilling process starts. Be sure to

saw machine.

use lubricant to reduce friction bit and block.

2. Next, the block is placed

in the power saw machine Chamfering

and clamped tightly when

the position of the power 9. The Final step to completing the L- Shaped block is

saw is finalised. chamfering.

3. After that, the blade of the power 10. A square of 10mm sides is marked at the ends of

saw is lowered down just before it is the block using a Vernier height gauge.

slightly above the block. The switch is

switched on and the 50mm mark is to 11. The block is first clamped onto a working table. By

using a hacksaw, the centre of the 10mm square is

be cut off. The cutting speed of the marked first. Then, it is cut off. The same process for all

power saw machine is to be set a

one(1), to produce a fine and smooth ends of the block.

surface on the block.