Page 8 - File 1

P. 8

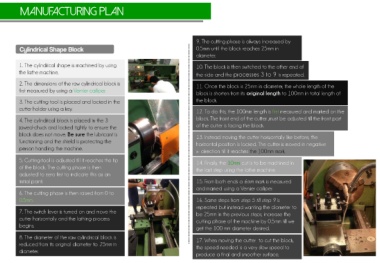

Manufacturing plan

9. The cutting phase is always increased by

Cylindrical Shape Block 0.5mm until the block reaches 25mm in

diameter.

1. The cylindrical shape is machined by using 10. The block is then switched to the other end of

the lathe machine. the side and the processes 3 to 9 is repeated.

2. The dimensions of the raw cylindrical block is 11. Once the block is 25mm in diameter, the whole length of the

first measured by using a Vernier calliper. block is shorten from its original length to 100mm in total length of

3. The cutting tool is placed and locked in the the block.

cutter holder using a key.

12. To do this, the 100mm length is first measured and marked on the

4. The cylindrical block is placed in the 3 block. The front end of the cutter ,must be adjusted till the front part

jawed-chuck and locked tightly to ensure the of the cutter is facing the block.

block does not move. Be sure the lubricant is 13. Instead moving the cutter horizontally like before, the

functioning and the shield is protecting the horizontal position is locked. The cutter is moved in negative

person handling the machine. x- direction till it reaches the 100mm mark.

5. Cutting tool is adjusted till it reaches the tip 14. Finally, the 10mm cut is to be machined in

of the block. The cutting phase is then the last step using the lathe machine.

adjusted to zero first to indicate this as an

initial point. 15. From both ends a 6mm mark is measured

and marked using a Vernier calliper.

6. The cutting phase is then raised from 0 to

0.5mm. 16. Same steps from step 5 till step 9 is

repeated but instead wanting the diameter to

7. The switch lever is turned on and move the be 25mm in the previous steps, increase the

cutter horizontally and the lathing process cutting phase of the machine by 0.5mm till we

begins.

get the 100 mm diameter desired.

8. The diameter of the raw cylindrical block is 17. When moving the cutter to cut the block,

reduced from its original diameter to 25mm in the speed needed is a very slow speed to

diameter.

produce a final and smoother surface.