Page 127 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 127

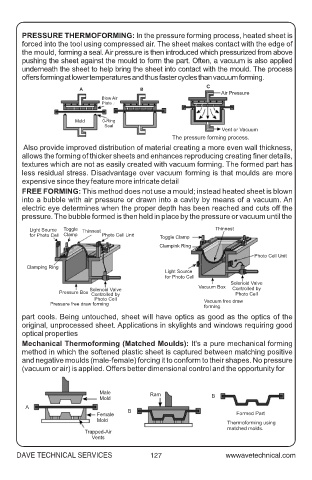

PRESSURE THERMOFORMING: In the pressure forming process, heated sheet is

forced into the tool using compressed air. The sheet makes contact with the edge of

the mould, forming a seal. Air pressure is then introduced which pressurized from above

pushing the sheet against the mould to form the part. Often, a vacuum is also applied

underneath the sheet to help bring the sheet into contact with the mould. The process

offers forming at lower temperatures and thus faster cycles than vacuum forming.

C

A B

Air Pressure

Blow Air

Plate

Mold 0-Ring

Seal

Vent or Vacuum

The pressure forming process.

Also provide improved distribution of material creating a more even wall thickness,

allows the forming of thicker sheets and enhances reproducing creating finer details,

textures which are not as easily created with vacuum forming. The formed part has

less residual stress. Disadvantage over vacuum forming is that moulds are more

expensive since they feature more intricate detail

FREE FORMING: This method does not use a mould; instead heated sheet is blown

into a bubble with air pressure or drawn into a cavity by means of a vacuum. An

electric eye determines when the proper depth has been reached and cuts off the

pressure. The bubble formed is then held in place by the pressure or vacuum until the

Light Source Toggle Thinnest Thinnest

for Photo Cell Clamp Photo Cell Unit Toggle Clamp

Clampink Ring

Photo Cell Unit

Clamping Ring

Light Source

for Photo Cell

Solenoid Valve

Vacuum Box

Solenoid Valve Controlled by

Pressure Box

Controlled by Photo Cell

Photo Cell

Pressure free draw forming Vacuum free draw

forming.

part cools. Being untouched, sheet will have optics as good as the optics of the

original, unprocessed sheet. Applications in skylights and windows requiring good

optical properties

Mechanical Thermoforming (Matched Moulds): It's a pure mechanical forming

method in which the softened plastic sheet is captured between matching positive

and negative moulds (male-female) forcing it to conform to their shapes. No pressure

(vacuum or air) is applied. Offers better dimensional control and the opportunity for

Male Ram

Mold B

A

B

Female Formed Part

Mold

Thermoforming using

matched molds.

Trapped-Air

Vents

DAVE TECHNICAL SERVICES 127