Page 132 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 132

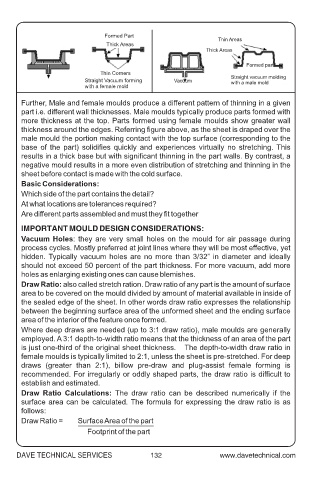

Formed Part

Thin Areas

Thick Areas

Thick Areas

Formed part

Thin Corners

Straight vacuum molding

Straight Vacuum forming Vacuum with a male mold

with a female mold

Further, Male and female moulds produce a different pattern of thinning in a given

part i.e. different wall thicknesses. Male moulds typically produce parts formed with

more thickness at the top. Parts formed using female moulds show greater wall

thickness around the edges. Referring figure above, as the sheet is draped over the

male mould the portion making contact with the top surface (corresponding to the

base of the part) solidifies quickly and experiences virtually no stretching. This

results in a thick base but with significant thinning in the part walls. By contrast, a

negative mould results in a more even distribution of stretching and thinning in the

sheet before contact is made with the cold surface.

Basic Considerations:

Which side of the part contains the detail?

At what locations are tolerances required?

Are different parts assembled and must they fit together

IMPORTANT MOULD DESIGN CONSIDERATIONS :

Vacuum Holes: they are very small holes on the mould for air passage during

process cycles. Mostly preferred at joint lines where they will be most effective, yet

hidden. Typically vacuum holes are no more than 3/32” in diameter and ideally

should not exceed 50 percent of the part thickness. For more vacuum, add more

holes as enlarging existing ones can cause blemishes.

Draw Ratio: also called stretch ration. Draw ratio of any part is the amount of surface

area to be covered on the mould divided by amount of material available in inside of

the sealed edge of the sheet. In other words draw ratio expresses the relationship

between the beginning surface area of the unformed sheet and the ending surface

area of the interior of the feature once formed.

Where deep draws are needed (up to 3:1 draw ratio), male moulds are generally

employed. A 3:1 depth-to-width ratio means that the thickness of an area of the part

is just one-third of the original sheet thickness. The depth-to-width draw ratio in

female moulds is typically limited to 2:1, unless the sheet is pre-stretched. For deep

draws (greater than 2:1), billow pre-draw and plug-assist female forming is

recommended. For irregularly or oddly shaped parts, the draw ratio is difficult to

establish and estimated.

Draw Ratio Calculations: The draw ratio can be described numerically if the

surface area can be calculated. The formula for expressing the draw ratio is as

follows:

Draw Ratio = Surface Area of the part

Footprint of the part

DAVE TECHNICAL SERVICES 132