Page 130 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 130

Parts formed by the slip-ring method generally exhibit excellent uniformity in wall

thickness. In this production method, the sheet is not gripped as tightly as it is being

formed, which can help in getting more material out of the clamping frame and into the

part.

Twin sheet forming:

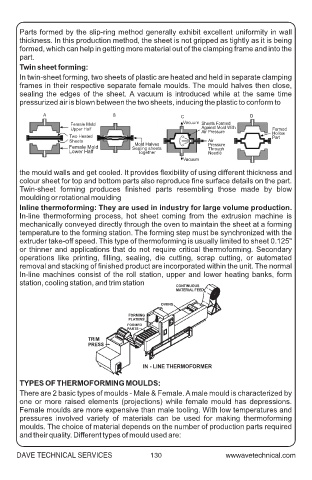

In twin-sheet forming, two sheets of plastic are heated and held in separate clamping

frames in their respective separate female moulds. The mould halves then close,

sealing the edges of the sheet. A vacuum is introduced while at the same time

pressurized air is blown between the two sheets, inducing the plastic to conform to

A B C D

Female Mold Vacuum Sheets Formed

Upper Half Against Mold With Formed

Air Pressure Hollow

Two Heated Part

Sheets Air

Mold Halves

Female Mold Sealing sheets Pressure

Through

Lower Half Together Needle

Vacuum

the mould walls and get cooled. It provides flexibility of using different thickness and

colour sheet for top and bottom parts also reproduce fine surface details on the part.

Twin-sheet forming produces finished parts resembling those made by blow

moulding or rotational moulding

Inline thermoforming: They are used in industry for large volume production.

In-line thermoforming process, hot sheet coming from the extrusion machine is

mechanically conveyed directly through the oven to maintain the sheet at a forming

temperature to the forming station. The forming step must be synchronized with the

extruder take-off speed. This type of thermoforming is usually limited to sheet 0.125"

or thinner and applications that do not require critical thermoforming. Secondary

operations like printing, filling, sealing, die cutting, scrap cutting, or automated

removal and stacking of finished product are incorporated within the unit. The normal

In-line machines consist of the roll station, upper and lower heating banks, form

station, cooling station, and trim station

CONTINUOUS

MATERIAL FEED

OVENS

FORMING

PLATENS

FORMED

PARTS

TRIM

PRESS

IN - LINE THERMOFORMER

TYPES OF THERMOFORMING MOULDS:

There are 2 basic types of moulds - Male & Female. A male mould is characterized by

one or more raised elements (projections) while female mould has depressions.

Female moulds are more expensive than male tooling. With low temperatures and

pressures involved variety of materials can be used for making thermoforming

moulds. The choice of material depends on the number of production parts required

and their quality. Different types of mould used are:

DAVE TECHNICAL SERVICES 130