Page 131 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 131

Wood Moulds/Patterns - They are generally used for low-production part runs or

initial design phase. They are relatively inexpensive and allow makes changes in

design very easily. On finalization of design and part specifications, the wood pattern

is then used to create a ceramic composite mould, or cast aluminium mould for

regular production.

Aluminium Moulds: They can be cast or machined. The advantages of aluminium

are its durability, good heat conductivity allowing faster cycle time and ease of

machining. Typically have temperature control lines with hot water or radiant heat

running through them to speed up production by regulating the heat of the plastic

being formed.

Cast AL moulds are casted in foundry. Alternatively, moulds are cut out of a solid

block of AL using a CNC machine and CAD program and are used for shallow draw

parts out of thin gauge material. Drawback with this type of mould is cost.

Steel Moulds: Durable moulds for most simple parts can be machined from

standard steel stock. Steel moulds are generally easy to plate but are usually

expensive to build.

Electroformed Moulds: These permanent metal moulds, are produced using

successive layers of copper, nickel, and chromium. The metal layers are formed into

a shell. These moulds can achieve precise mould details and produce parts with

excellent surface finish.

Plaster moulds: Inexpensive, easily shaped moulds can also be cast from

plaster. Plaster moulds are typically used for prototyping or on parts with small

runs. Poor durability, lack of heat conductivity, and the inability to control

temperature make them unsuitable for large production volumes.

Composite Moulds - Composite moulds are durable and temperature-resistant

moulds used for rapid forming cycles. They offer lower cost alternative to cast or

machined aluminum moulds. Composite moulds are typically made from filled

phenolic, polyester, polyurethane or epoxy resins, offers excellent dimensional

stability, good abrasion resistance and a smooth surface.

Important Considerations for Mould Construction

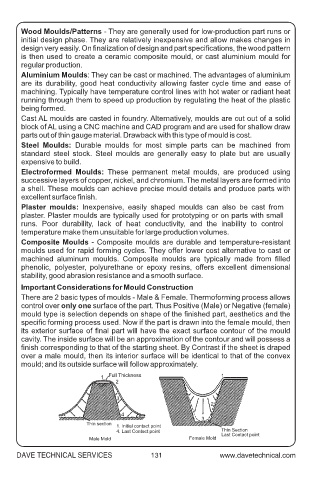

There are 2 basic types of moulds - Male & Female. Thermoforming process allows

control over only one surface of the part. Thus Positive (Male) or Negative (female)

mould type is selection depends on shape of the finished part, aesthetics and the

specific forming process used. Now if the part is drawn into the female mould, then

its exterior surface of final part will have the exact surface contour of the mould

cavity. The inside surface will be an approximation of the contour and will possess a

finish corresponding to that of the starting sheet. By Contrast if the sheet is draped

over a male mould, then its interior surface will be identical to that of the convex

mould; and its outside surface will follow approximately.

1 Full Thickness 1

2

3

2

4

3

Thin section

1. Initial contact point

4. Last Contact point Thin Section

Last Contact point

Male Mold Female Mold

DAVE TECHNICAL SERVICES 131