Page 129 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 129

A B

Vacuum C D

Switch

Clamp

Switch starts Vacuum Atmosphere Formed Part

Vacuum Box Vacuum snap-back thermoforming.

and stops Vacuum

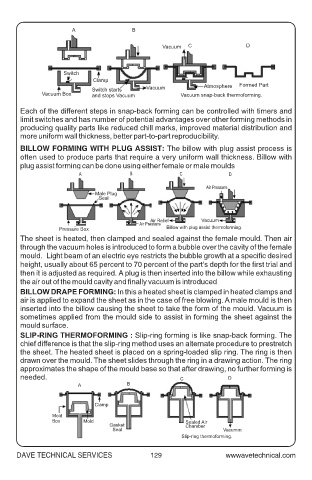

Each of the different steps in snap-back forming can be controlled with timers and

limit switches and has number of potential advantages over other forming methods in

producing quality parts like reduced chill marks, improved material distribution and

more uniform wall thickness, better part-to-part reproducibility.

BILLOW FORMING WITH PLUG ASSIST: The billow with plug assist process is

often used to produce parts that require a very uniform wall thickness. Billow with

plug assist forming can be done using either female or male moulds

A B C D

Air Pressure

Male Plug

Seal

Air Relief Vacuum

Air Pressure

Pressure Box Billow with plug assist thermoforming.

The sheet is heated, then clamped and sealed against the female mould. Then air

through the vacuum holes is introduced to form a bubble over the cavity of the female

mould. Light beam of an electric eye restricts the bubble growth at a specific desired

height, usually about 65 percent to 70 percent of the part's depth for the first trial and

then it is adjusted as required. A plug is then inserted into the billow while exhausting

the air out of the mould cavity and finally vacuum is introduced

BILLOW DRAPE FORMING: In this a heated sheet is clamped in heated clamps and

air is applied to expand the sheet as in the case of free blowing. A male mould is then

inserted into the billow causing the sheet to take the form of the mould. Vacuum is

sometimes applied from the mould side to assist in forming the sheet against the

mould surface.

SLIP-RING THERMOFORMING : Slip-ring forming is like snap-back forming. The

chief difference is that the slip-ring method uses an alternate procedure to prestretch

the sheet. The heated sheet is placed on a spring-loaded slip ring. The ring is then

drawn over the mould. The sheet slides through the ring in a drawing action. The ring

approximates the shape of the mould base so that after drawing, no further forming is

needed. C D

A B

Clamp

Mold

Box Mold Sealed Air

Gasket Chamber

Seal Vacumm

Slip-ring thermoforming.

DAVE TECHNICAL SERVICES 129