Page 118 - Maxwell House

P. 118

98 Chapter 2

The next step is to introduce, at last formally, the graphene complex dielectric constant ()

following the expression (2.80) and assuming that = / and d = 0.34 nm

′ ′′

() + ′′ ′

() ≅ 1 − = 1 − = (1 + ⁄ ) − (2.103)

⁄

0

0

0 0

Note that the imaginary part of conductivity contributes to the real part of graphene permittivity.

We can see that () is negative in the entire frequency range in the same manner as for copper

′

(compare Figure 2.9.3 and 2.5.2). The absolute values of both () and () decrease with

′

′′

the increasing frequency in the transition from good conductor to semiconductor. We can expect

that graphene will become some kind of dielectric at higher frequencies. Indeed, its relative

permittivity in visible range is ≅ 5.5 − ( )⁄ 0 that gives ≅ 5.5 + 5.84 for the

wavelength of 546 nm. Note some essential graphene features without further elaboration:

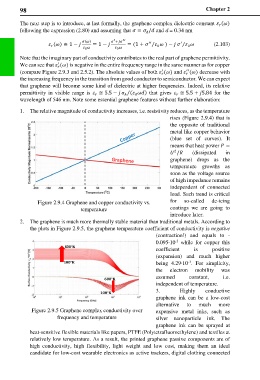

1. The relative magnitude of conductivity increases, i.e. resistivity reduces, as the temperature

rises (Figure 2.9.4) that is

the opposite of traditional

metal like copper behavior

(blue set of curves). It

means that heat power =

/ (dissipated in

2

graphene) drops as the

temperature growths as

soon as the voltage source

of high impedance remains

independent of connected

load. Such trend is critical

Figure 2.9.4 Graphene and copper conductivity vs. for so-called de-icing

temperature coatings we are going to

introduce later.

2. The graphene is much more thermally stable material than traditional metals. According to

the plots in Figure 2.9.5, the graphene temperature coefficient of conductivity is negative

(contraction!) and equals to -

-3

0.095∙10 while for copper this

60

coefficient is positive

(expansion) and much higher

1 being 4.29∙10 . For simplicity,

-3

the electron mobility was

assumed constant, i.e.

independent of temperature.

3. Highly conductive

graphene ink can be a low-cost

alternative to much more

Figure 2.9.5 Graphene complex conductivity over expensive metal inks, such as

frequency and temperature silver nanoparticle ink. The

graphene ink can be sprayed at

heat-sensitive flexible materials like papers, PTFE (Polytetrafluoroethylene) and textiles at

relatively low temperature. As a result, the printed graphene passive components are of

high conductivity, high flexibility, light weight and low cost, making them an ideal

candidate for low-cost wearable electronics as active trackers, digital clothing connected