Page 122 - Maxwell House

P. 122

102 Chapter 2

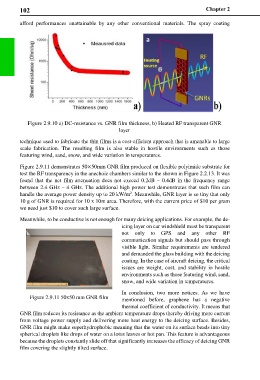

afford performances unattainable by any other conventional materials. The spray coating

Figure 2.9.10 a) DC-resistance vs. GNR film thickness, b) Heated RF transparent GNR

layer

technique used to fabricate the thin films is a cost-efficient approach that is amenable to large

scale fabrication. The resulting film is also stable in hostile environments such as those

featuring wind, sand, snow, and wide variation in temperatures.

Figure 2.9.11 demonstrates 50×50mm GNR film produced on flexible polyimide substrate for

test the RF transparency in the anechoic chambers similar to the shown in Figure 2.2.13. It was

found that the net film attenuation does not exceed 0.2dB – 0.4dB in the frequency range

between 2.4 GHz – 4 GHz. The additional high power test demonstrates that such film can

handle the average power density up to 20 kW/m . Meanwhile, GNR layer is so tiny that only

2

10 g of GNR is required for 10 x 10m area. Therefore, with the current price of $10 per gram

we need just $10 to cover such large surface.

Meanwhile, to be conductive is not enough for many deicing applications. For example, the de-

icing layer on car windshield must be transparent

not only to GPS and any other RF

communication signals but should pass through

visible light. Similar requirements are tendered

and demanded the glass building with the deicing

coating. In the case of aircraft deicing, the critical

issues are weight, cost, and stability in hostile

environments such as those featuring wind, sand,

snow, and wide variation in temperatures.

In conclusion, two more notices. As we have

Figure 2.9.11 50x50 mm GNR film mentioned before, graphene has a negative

thermal coefficient of conductivity. It means that

GNR film reduces its resistance as the ambient temperature drops thereby driving more current

from voltage power supply and delivering more heat energy to the deicing surface. Besides,

GNR film might make superhydrophobic meaning that the water on its surface beads into tiny

spherical droplets like drops of water on a lotus leaves or hot pan. This feature is advantageous

because the droplets constantly slide off that significantly increases the efficacy of deicing GNR

film covering the slightly tilted surface.