Page 476 - Maxwell House

P. 476

456 Chapter 9

The primary drawbacks of FEM technique are:

• “… The explicit expression for updating EM field in time-domain cannot be derived in the

general case. Instead, a linear system of equations has to be solved to update the field. … FEM

requires more computer resources, both in term of CPU time and memory.” [8, 9].

• The PMLs truncating the solution domain are needed in case of unbounded areas.

• FEM code is rather difficult to parallelize efficiently.

Now let come back to Perfectly Matched Layers whose presence is mandatory in many

numerical codes. It is worthy to point out that these layers are the artificial physical objects and

not the special boundary conditions as some publications treat them.

9.1.3 Perfectly Matched Layer (PML)

Frequently, the project model is open to exterior free space, i.e. unbounded, and thus some EM

waves escape to infinity that includes far-field radiation (antenna, not entirely shielded PCB,

etc.). If so, the application of explicit FDTD and many other codes becomes slightly more

complicated. For example, any FDTD computation domain should cover not only the model

area but the whole surrounding, i.e. the entire universe. Evidently, it makes the numerical

solution impractical demanding a computer with infinite memory running for unlimited time.

To go around this issue, J. P. Berenger proposed in 1994 to enclose such “open” models into

the virtual 3D cavity of a simple shape like parallelepiped or sphere with virtual walls

comprising several layers of artificial absorbing materials. Apparently, the fundamental goal

will be achieved if such material is utterly absorbing at all frequencies, polarizations, and angles

of incidence. Furthermore, it should be able to almost entirely attenuate the radiated fields on

the length of just a few cells, i.e. this extra cavity may be implemented with the minimum of

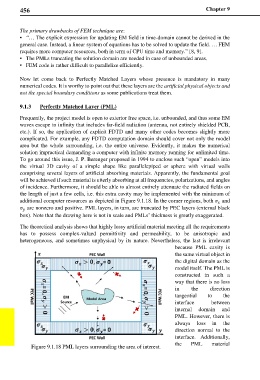

additional computer resources as depicted in Figure 9.1.18. In the corner regions, both and

are nonzero and positive. PML layers, in turn, are truncated by PEC layers (external black

box). Note that the drawing here is not in scale and PMLs’ thickness is greatly exaggerated.

The theoretical analysis shows that highly lossy artificial material meeting all the requirements

has to possess complex-valued permittivity and permeability, to be anisotropic and

heterogeneous, and sometimes unphysical by its nature. Nevertheless, the last is irrelevant

because PML cavity is

the same virtual object in

the digital domain as the

model itself. The PML is

constructed in such a

way that there is no loss

in the direction

tangential to the

interface between

internal domain and

PML. However, there is

always loss in the

direction normal to the

interface. Additionally,

Figure 9.1.18 PML layers surrounding the area of interest. the PML material