Page 436 - Wago_AutomationTechnology_Volume3_2015_US.pdf

P. 436

6 I/O-System — SPEEDWAY

434 Application and Installation Instructions

Power supply

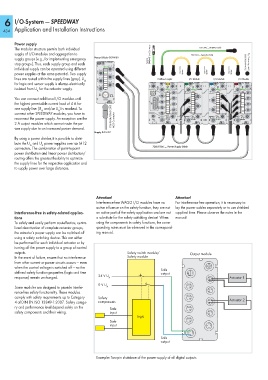

The modular structure permits both individual 756-120x/..., ETHERNET Cable

supply of I/O modules and aggregation to ETHERNET RJ-45 Connector 756-130x/..., System Bus Cable

supply groups (e.g., for implementing emergency Power Divider 767-9101 750-975

stop groups). Thus, each supply group and each PWR DVI 756-9409/0060-0000 System Terminating Plug

individual supply can be operated using different X 6 767-0111 767-0111 767-0111

power supplies at the same potential. Two supply X 5 Spacer Spacer Spacer

X

lines are routed within the supply lines (gray). U X 4 Fieldbus Coupler I/O Module I/O Module I/O Module

LS 3

for logic and sensor supply is always electrically X ETHERNET FC 8DI 4AI RTD 4AO U/I 8DO 2A

2 SBM

isolated from U for the actuator supply. X 1 1 FB 2

A

MS 1 CS X X

7 8 Ch4 Ch4 7 8

24 V NS 2 PS

X 7 U LS U A ACT/LNK X 7 6 X X X 7 6

You can connect additional I/O modules until 767-9101 12I RES 5 X 6 X Ch3 Er4 4 X Ch3 Er4 4 5 X 6

11I B/E

9I SN 8I 27 X 4 3 3 X 4

the highest permissible current load of 4 A for 7I 26 6I 25 5I 24 4I 23 5 3 X 4 Er3 Ch2 X Er3 Ch2 X 5 3 X 4

one supply line (U and/or U ) is reached. To 3I 22 2I 21 1I 20 X 3 2 X X Ch1 Er2 2 X Ch1 Er2 2 X 3 2 X

LS A 1 2 1 1 1 2

connect other SPEEDWAY modules, you have to X 1 0 Er1 Er1 X 1 0

24 V

24 V

24 V

24 V

reconnect the power supply. An exception are the 756-9604/0060-0000 M23 Connector COM 767-1301 767-6402 767-7401 767-4803

U LS U A

U LS U A

U LS U A

U LS U A

2 A output modules which cannot route the po-

wer supply due to an increased power demand.

Supply 24 V DC

By using a power divider, it is possible to distri-

bute the U and U power supplies over six M12

LS A 756-310x/..., Power Supply Cable

connectors. The combination of point-to-point

power distribution and linear power distribution/

routing offers the greatest flexibility to optimize

the supply lines for the respective application and

to supply power over large distances.

Attention! Attention!

Interference-free WAGO I/O modules have no For interference-free operation, it is necessary to

active influence on the safety function, they are not lay the power cables separately or to use shielded

Interference-free in safety-related applica- an active part of the safety application and are not supplied lines. Please observe the notes in the

tions a substitute for the safety switching device! When manual!

To safely and easily perform cost-effective, centra- using the components in safety functions, the corre-

lized deactivation of complete actuator groups, sponding notes must be observed in the correspond-

the actuator’s power supply can be switched off ing manual.

using a safety switching device. This can either

be performed for each individual actuator or by

turning off the power supply to a group of control

outputs. Safety switch module/ Output module

In the event of failure, ensure that no interference Safety module

from other current or power circuits occurs — even

when the control voltage is switched off — so the Safe

defined safety function properties (logic and time output

response) remain unchanged. 24 V U A Actuator 1

0 V U

Some modules are designed to provide interfe- A

rence-free safety functionality. These modules

comply with safety requirements up to Category Safety

4 of DIN EN ISO 13849-1:2007. Safety catego- components Actuator 2

ry and performance level depend solely on the

Safe

safety components and their wiring. input

Logic

Safe

input

Safe

output

Example: Two-pin shutdown of the power supply of all digital outputs