Page 340 - Schmalz - Vacuum Components

P. 340

EN_Spezialgreifer.book Seite 340 Donnerstag, 25. Februar 2016 6:05 18

PA01019111_inh_EN.pdf

Wafer Grippers

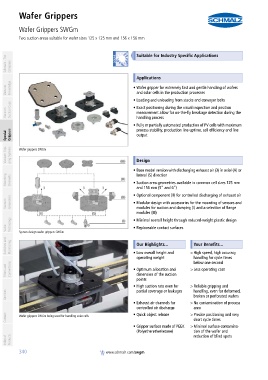

Wafer Grippers SWGm

PA01019111_inh_EN.pdf Two suction areas suitable for wafer sizes 125 x 125 mm and 156 x 156 mm PA01019111_inh_EN.pdf

container

Schmalz - The Company Suitable for Industry Specific Applications

container

Applications

Vacuum Knowledge • Wafer gripper for extremely fast and gentle handling of wafers

and solar cells in the production processes

• Loading and unloading from stacks and conveyor belts

Vacuum Suction Cups • Exact positioning during the visual inspection and position

measurement allow for on-the-fly breakage detection during the

handling process

• Fully or partially automated production of PV cells with maximum

Special Grippers process stability, production line uptime, cell efficiency and line

output

Vacuum Grip- ping Systems Wafer grippers SWGm Design

container

• Base model version with discharging exhaust air (3) in axial (A) or

Mounting Elements • Suction area geometries available in common cell sizes 125 mm

lateral (S) direction

and 156 mm (5" and 6")

• Optional component (II) for controlled discharging of exhaust air

Vacuum Generators • Modular design with accessories for the mounting of sensors and

modules for suction and damping (I) and a selection of flange

modules (III)

• Minimal overall height through reduced-weight plastic design

Valve Technology System design wafer grippers SWGm • Replaceable contact surfaces

Switches and Monitoring container Our Highlights... Your Benefits...

• Low overall height and

operating weight >High speed, high accuracy

handling for cycle times

below one second

Filters and Connections • Optimum allocation and >Less operating cost

dimension of the suction

points

• High suction rate even for >Reliable gripping and

Services partial coverage or leakages handling, even for deformed,

broken or perforated wafers

• Exhaust air channels for >No contamination of process

controlled air discharge area

Contact Wafer grippers SWGm being used for handling solar cells • Quick object release >Precise positioning and very

short cycle times

• Gripper surface made of PEEK >Minimal surface contamina-

(Polyetheretherketone) tion of the wafer and

Index of Products reduction of blind spots

340 www.schmalz.com/swgm

container

PA01019111_inh_EN.pdf