Page 612 - Wago_PCB_TerminalBlocksConnectors_Volume2_2015_US

P. 612

13 Processing Information and Material Specifications

610

Soldering Information

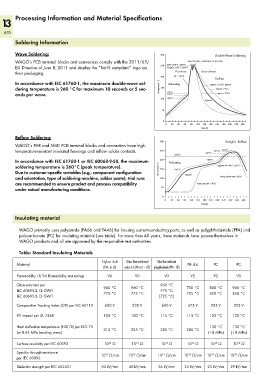

Wave Soldering: 300 Double-Wave Soldering

WAGO’s PCB terminal blocks and connectors comply with the 2011/65/ SnPb: 235°C-260°C ..................

max.10s, max. contact time 5s per wave

EU Directive of June 8, 2011 and display the “RoHS compliant” logo on 250 SnAgCu: 250°C-260°C

First wave

their packaging. 200 ∆T < 150 K Second wave

Cooling

In accordance with IEC 61760-1, the maximum double-wave sol- Preheating ............. approx. 3.5 K/s typical

dering temperature is 260 °C for maximum 10 seconds or 5 sec- Temperature °C 150 ........... approx. 2 K/s

onds per wave. 130°C ........................... .............................. approx. 5 K/s

120°C ............................

100 100°C ............................ Typical

50

0

0 20 40 60 80 100 120 140 160 180 200 220 240

Time (s)

Reflow Soldering:

300 SnAgCu Reflow

WAGO‘s THR and SMD PCB terminal blocks and connectors have high-

temperature-resistant insulated housings and reflow solder contacts. 250 220°C 250°C ......

245°C ..............

235°C ........................

In accordance with IEC 61760-1 or IEC 60068-2-58, the maximum 200 Preheating 180°C

soldering temperature is 260°C (peak temperature). 150 150°C approx. 45-90s > 220°C

Due to customer-specific variables (e.g., component configuration Temperature °C Typical

and orientation, type of soldering machine, solder paste), trial runs 100 Ramp down rate < 6K/s

are recommended to ensure product and process compatibility Ramp up rate < 3K/s

under actual manufacturing conditions. 50

0

0 30 60 90 120 150 180 210 240 270 300 330 360

Time(s)

Insulating material

WAGO primarily uses polyamide (PA66 and PA46) for housing current-conducting parts, as well as polyphthalamide (PPA) and

polycarbonate (PC) for insulating material (see table). For more than 40 years, these materials have proven themselves in

WAGO products and all are approved by the responsible test authorities.

Table: Standard Insulating Materials

Nylon 6.6 Glass fiber-reinforced Glass fiber reinforced

Material PA 4.6 PC PC

(PA 6.6) nylon 6.6 (PA 6.6 – GF) polyphthalamide (PPA – GF)

Flammability UL 94 flammability test ratings V0 V0 V0 V2 V2 V0

Glow-wire test per 960 °C 960 °C 960 °C 750 °C 800 °C 960 °C

IEC 60695-2-12 GWFI 775 °C 775 °C 775 °C 725 °C 850 °C 850 °C

IEC 60695-2-13 GWIT (725 °C)

Comparative Tracking Index (CTI) per IEC 60112 600 V 230 V 600 V 375 V 225 V 225 V

RTI impact per UL 746B 105 °C 100 °C 115 °C 115 °C 125 °C 120 °C

Heat deflection temperature (HDT/B) per ISO 75 215 °C 235 °C 285 °C 280 °C 130 °C 130 °C

(at 0.45 MPa bending stress) (1.8 MPa) (1.8 MPa)

Surface resistivity per IEC 60093 10 Ω 10 Ω 10 Ω 10 Ω 10 Ω 10 Ω

13

12

12

15

15

15

Specific through resistance 10 Ω/cm 10 Ω/cm 10 Ω/cm 10 Ω/cm 10 Ω/cm 10 Ω/cm

11

13

15

13

13

15

per IEC 60093

Dielectric strength per IEC 60243-1 30 kV/mm 40 kV/mm 26 kV/mm 25 kV/mm 25 kV/mm 29 kV/mm