Page 5 - Parker - High purity chemicals in electronic application

P. 5

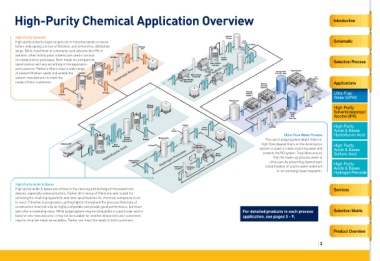

High-Purity Chemical Application Overview Introduction

High-Purity Solvents Absorber

Column

High-purity solvents begin as general or industrial grade versions Dilution Schematic

Acid

before undergoing a series of filtration, and sometimes, distillation Storage DI Water

steps. While most think of commonly used solvents like IPA or Tank

acetone, other mostly polar solvents are used in various Distillation Distillation

microelectronics processes. Both metal ion and particle Purier Selection Process

Column

specifications will vary according to the application Hydrolyzer Sulfur Trioxide

UHP Sulfuric Acid

Vaporizer

and customer. Parker’s filters meet a wide range Sulfur Trioxide

Liquid

Storage Tank

of solvent filtration needs and enable the Absorber Isopropyl Alcohol Sulfur Trioxide Storage & Air Vent Filter Degasication

solvent manufacturer to meet the Sulfate Condensor Station

UV

Esters

needs of their customers. Sulfur Trioxide Applications

Evaporator

Reverse

Osmosis

System 2

Reverse

DI Water Ultra-Pure

Propene Osmosis

System 1

EDI Water (UPW)

Pretreatment

Tank

Sulfuric Ultapure Ion

Ultra-Pure Water Vent Filter Solvents Isopropyl

Acid Dilute HF Exchange High-Purity

Storage

Alcohol (IPA)

Tank

& Air

DI Water Oxidizer Ion High-Purity

Water Exchange

O2 Recycle Acids & Bases

Rich Air

Ultra-Pure Water Process Hydrouoric Acid

Storage Hydrogenator

Ultrapure DI Water The use of polypropylene depth filters or

Aquesous HF

Anhydrous HF Distillation Hydrogen Purication high-flow pleated filters on the deionization High-Purity

Final

Solvent

Concentrated system is used to treats incoming water and Acids & Bases

Aqueous HF Hydrouoric Acid Extractor protects the RO system. Trap filters ensure Sulfuric Acid

Liquid

that the make-up process water is

Anthraquinone

+ Solvent Hydrogen Peroxide ultra-pure by preventing downstream High-Purity

Purication Purication contamination of source water sediment Acids & Bases

Column 2 Column 1

or ion exchange bead migration. Hydrogen Peroxide

High-Purity Acids & Bases

High-purity acids & bases are critical to the cleaning and etching of microelectronic Services

devices, especially semiconductors. Parker dh’s lineup of filters are well suited for

achieving the challenging particle and ionic specifications the chemical companies need

to meet. Filtration is progressive, getting tighter throughout the process. Materials of

construction must not only be highly compatible and provide good performance, but must

also offer outstanding value. While polypropylene may be compatible in a particular acid or For detailed products in each process Selection Matrix

base for one manufacturer, it may not be suitable for another whose end user customers application, see pages 5 - 9.

require ultra low metal extractables. Parker can meet the needs of both customers.

Product Overview

| 3