Page 9 - Parker - High purity chemicals in electronic application

P. 9

Absorber

Acid

DI Water

Tank

Distillation

Purier

Sulfur Trioxide

UHP Sulfuric Acid

Vaporizer

Isopropyl Alcohol

Liquid

Storage

Storage Tank

Sulfur Trioxide

Condensor

UV

Esters

Evaporator

Reverse

System 2

Reverse

Propene Absorber Sulfate Hydrolyzer DI Water Distillation Storage Sulfur Trioxide Sulfur Trioxide Column Column Dilution Osmosis Osmosis & Air Vent Filter Degasication Station

System 1

EDI

Pretreatment

High-Purity Acids & Bases Dilute HF Introduction Exchange

Tank

Ion

Sulfuric

Ultapure

Acid

Hydrofluoric Acid 5 Ultra-Pure Water Storage

Tank

& Air

Schematic Vent Filter

3

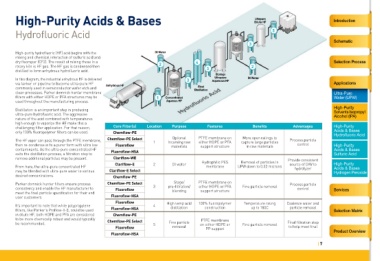

High-purity hydrofluoric (HF) acid begins with the DI Water Oxidizer Ion

mixing and chemical interaction of sulfuric acid and Water Exchange

Recycle

dry fluorspar (CF2). The result of mixing those in a 4 Rich Air Selection Process

O2

rotary kiln is HF gas. The HF gas is condensed then 2 2

distilled to form anhydrous hydrofluoric acid. 3

Storage Hydrogenator

In this diagram, the industrial anhydrous HF is delivered 3 Ultrapure DI Water

via tanker or pipeline to become ultra-pure HF Aquesous HF Applications

commonly used in semiconductor wafer etch and Anhydrous HF Final Hydrogen Solvent

Purication

clean processes. Parker domnick hunter membrane Distillation Ultra-Pure

filters with either HDPE or PFA structures may be 1 Concentrated Water (UPW)

used throughout the manufacturing process. Aqueous HF Hydrouoric Acid Liquid

Distillation is an important step in producing Hydrogen Peroxide High-Purity Extractor

ultra-pure hydrofluoric acid. The aggressive Anthraquinone Solvents Isopropyl

Alcohol (IPA)

nature of the acid combined with temperatures + Solvent

high enough to vaporize the HF make this a

Purication

High-Purity

challenging filter application. For that reason, Core Filter(s) Location Purpose Features Benefits Advantages Purication

Column 2

Column 1

only 100% fluoropolymer filters can be used. Chemflow-PE Acids & Bases

Hydrouoric Acid

Optional

More open ratings to

The HF vapor can pass through the PTFE membrane, Chemflow-PE Select 1 Incoming raw PTFE membrane on capture large particles Process particle

either HDPE or PFA

then re-condense in to a purer form with ultra low Fluoroflow materials support structure in raw materials control High-Purity

contaminants. As the ultra-pure concentrated HF Acids & Bases

exits the distillation process, a filtration step to Fluoroflow-HSA Sulfuric Acid

remove additional particles may be present. Clariflow-WE Provide consistent

Clariflow-E 2 DI water Hydrophilic PES Removal of particles in source of DIW to High-Purity

From here, the ultra-pure concentrated HF membrane UPW down to 0.02 microns hydrolyzer Acids & Bases

may be blended with ultra-pure water to various Clariflow-E Select Hydrogen Peroxide

desired concentrations. Chemflow-PE

Parker domnick hunter filters ensure process Chemflow-PE Select Stage/ PTFE membrane on Process particle

consistency and enable the HF manufacturer to Fluoroflow 3 pre-filtration/ either HDPE or PFA Fine particle removal control Services

support structure

blending

meet the final particle specification for their end

user customers. Fluoroflow-HSA

Fluoroflow High temp acid 100% fluoropolymer Temperature rating Coalesce water and

It’s important to note that while polypropylene 4 distillation construction up to 180C particle removal

filters, like Parker’s Proflow-II-E, could be used Fluoroflow-HSA Selection Matrix

in dilute HF, both HDPE and PFA are considered Chemflow-PE

to be more chemically robust and would typically Chemflow-PE Select PTFE membrane

be recommended. 5 Fine particle on either HDPE or Fine particle removal Final filtration step

Fluoroflow removal PP support to help meet final

Fluoroflow-HSA Product Overview

| 7