Page 11 - Parker - High purity chemicals in electronic application

P. 11

Absorber

Column

Acid

DI Water

Storage

Tank

Distillation

Distillation

Purier

Column

Hydrolyzer

Sulfur Trioxide

Vaporizer

Isopropyl Alcohol

Liquid

Sulfur Trioxide

Degasication

Storage Tank

Storage

Absorber

Condensor

UV

Sulfate

Esters

Sulfur Trioxide

Evaporator

Reverse

Osmosis

System 2

DI Water

Osmosis

Propene

System 1

Tank

Ion

Sulfuric

Ultapure

Ultra-Pure Water

Acid

Dilute HF

Storage

Tank

& Air

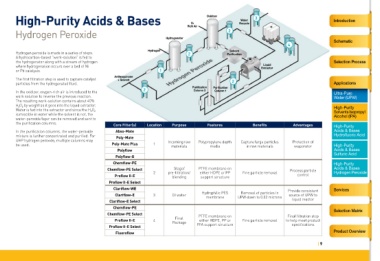

High-Purity Acids & Bases Oxidizer Sulfur Trioxide Water UHP Sulfuric Acid Pretreatment Dilution Reverse Introduction Exchange & Air Vent Filter Vent Filter Exchange Station EDI

DI Water

Ion

3

O2

Rich Air Recycle

Hydrogen Peroxide 2

Storage

Ultrapure DI Water Hydrogenator Schematic

Aquesous HF 4

Anhydrous HF Final

Solvent

Hydrouoric Acid

Hydrogen peroxide is made in a series of steps. Hydrogen 2 Purication

Distillation

A hydrocarbon-based “work-solution” is fed to

Concentrated

the hydrogenator along with a stream of hydrogen Selection Process

Aqueous HF

where hydrogenation occurs over a bed of Ni Liquid

or Pd catalysts. 1 Hydrogen Peroxide Extractor

The first filtration step is used to capture catalyst Anthraquinone

+ Solvent

particles from the hydrogenated fluid. 2 Applications

Column 2

Column 1

In the oxidizer, oxygen-rich air is introduced to the 2 Purication Purication Ultra-Pure

work solution to reverse the previous reaction. Water (UPW)

The resulting work-solution contains about 40%

H 2 O 2 by weight as it goes into the liquid extractor.

Water is fed into the extractor and since the H 2 O 2 High-Purity

is miscible in water while the solvent is not, the Solvents Isopropyl

Alcohol (IPA)

water-peroxide layer can be removed and sent to

the purification columns. Core Filter(s) Location Purpose Features Benefits Advantages High-Purity

In the purification columns, the water-peroxide Abso-Mate Acids & Bases

mixture is further concentrated and purified. For Poly-Mate Hydrouoric Acid

UHP hydrogen peroxide, multiple columns may Incoming raw Polypropylene depth Capture large particles Protection of

be used. Poly-Mate Plus 1 materials media in raw materials evaporator High-Purity

Polyflow Acids & Bases

Polyflow-G Sulfuric Acid

Chemflow-PE High-Purity

Chemflow-PE Select Stage/ PTFE membrane on Process particle Acids & Bases

2 pre-filtration/ either HDPE or PP Fine particle removal Hydrogen Peroxide

Proflow II-E blending support structure control

Proflow II-E Select

Clariflow-WE Provide consistent Services

Removal of particles in

Clariflow-E 3 DI water Hydrophilic PES UPW down to 0.02 microns source of UPW to

membrane

Clariflow-E Select liquid reactor

Chemflow-PE

Chemflow-PE Select PTFE membrane on Final filtration step Selection Matrix

Final

Proflow II-E 4 either HDPE, PP or Fine particle removal to help meet product

Package

Proflow II-E Select PFA support structure specifications

Fluoroflow Product Overview

| 9