Page 8 - Parker - High purity chemicals in electronic application

P. 8

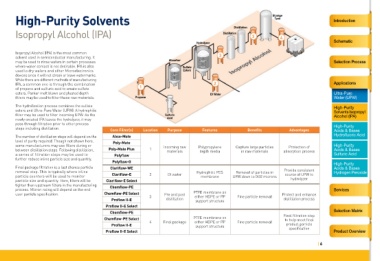

Absorber

Column

Acid

Dilution

DI Water

High-Purity Solvents Storage Introduction

Tank

Distillation

Isopropyl Alcohol (IPA) Distillation 3 4 Column

Purier

Hydrolyzer Schematic Sulfur Trioxide

UHP Sulfuric Acid

Vaporizer

Isopropyl Alcohol (IPA) is the most common Liquid

solvent used in semiconductor manufacturing. It 3 Sulfur Trioxide Storage Tank Degasication

Storage

may be used to rinse wafers in certain processes Absorber Isopropyl Alcohol Selection Process & Air Vent Filter

Sulfur Trioxide

where water contact is not desirable. IPA is also Sulfate Condensor UV

used to dry wafers and other Microelectronics Esters Sulfur Trioxide Station

devices since it will not streak or leave watermarks. Evaporator

While there are different methods of manufacturing Reverse

IPA, a common one is through the combination 2 Applications Osmosis

System 2

of propene and sulfuric acid to create sulfate 1

esters. Parker melt blown and pleated depth DI Water Ultra-Pure Reverse

filters may be used to filter these raw materials. Propene Water (UPW) Osmosis

System 1

The hydrolization process combines the sulfate High-Purity EDI

esters and Ultra-Pure Water (UPW). A hydrophilic Solvents Isopropyl Pretreatment

Tank

filter may be used to filter incoming UPW. As the Sulfuric Ultapure Alcohol (IPA) Ion

newly created IPA leaves the hydrolyzer, it may Acid Dilute HF Exchange

pass through filtration prior to other process

steps including distillation. Core Filter(s) Location Purpose Features Benefits Advantages High-Purity Ultra-Pure Water Storage

Acids & Bases

Tank

& Air

The number of distillation steps will depend on the Abso-Mate Hydrouoric Acid Vent Filter

level of purity required. Though not shown here, Poly-Mate

some manufacturers may use filters during or Incoming raw Polypropylene Capture large particles Protection of High-Purity

between distillation steps. Following distillation, Poly-Mate Plus 1 materials DI Water depth media in raw materials absorption process Acids & Bases Ion

Oxidizer

a series of filtration steps may be used to Polyflow Sulfuric Acid Water Exchange

O2

further reduce inline particle size and quantity. Rich Air Recycle

Polyflow-G High-Purity

Final package filtration is a last chance particle Clariflow-WE Acids & Bases

Storage

removal step. This is typically where inline Hydrophilic PES Removal of particles in Provide consistent Hydrogen Peroxide

Hydrogenator

source of UPW to

Ultrapure

particle counters will be used to monitor Clariflow-E 2 DI water membrane UPW down to 0.02 microns DI Water

Aquesous HF

particle size and quantity. Here, filters will be Clariflow-E Select Anhydrous HF hydrolyzer

Final

tighter than upstream filters in the manufacturing Chemflow-PE Distillation Hydrogen Solvent

Hydrouoric Acid

process. Micron rating will depend on the end Services Purication

Concentrated

user particle specification. Chemflow-PE Select 3 Pre and post PTFE membrane on Fine particle removal Protect and enhance

either HDPE or PP

Aqueous HF

Liquid

Proflow II-E distillation support structure distillation process Extractor

Proflow II-E Select Hydrogen Peroxide

Chemflow-PE Anthraquinone Selection Matrix

+ Solvent

Chemflow-PE Select PTFE membrane on Final filtration step Purication Purication

to help meet final

Proflow II-E 4 Final package either HDPE or PP Fine particle removal product particle Column 2 Column 1

support structure

Proflow II-E Select specification Product Overview

| 6