Page 7 - Parker - High purity chemicals in electronic application

P. 7

Absorber

Acid

Storage

Tank

Distillation

Distillation

Purier

Column Column Dilution DI Water

Hydrolyzer Sulfur Trioxide

UHP Sulfuric Acid

Vaporizer

Isopropyl Alcohol Sulfur Trioxide & Air Vent Filter

Liquid

Sulfur Trioxide

Storage

Absorber Ultra-Pure Water (UPW) Storage Tank Degasication Introduction

Sulfate Condensor UV

Esters Sulfur Trioxide Station

Evaporator

Reverse Schematic

Osmosis 2

System 2

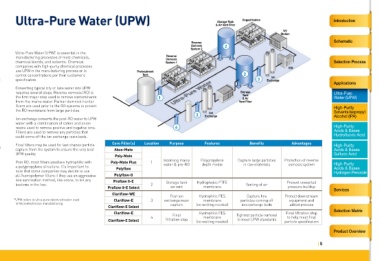

Ultra-Pure Water (UPW) is essential in the

*

Reverse

DI Water manufacturing processes of most chemicals, Osmosis

Propene chemical blends, and solvents. Chemical System 1 Selection Process

companies with high-purity chemical processes

use UPW in the manufacturing process or to Pretreatment EDI

control concentrations per their customer’s Tank 2

Sulfuric Ultapure specification. 3 Ion

Acid Dilute HF Exchange Applications

Converting typical city or lake water into UPW

requires several steps. Reverse osmosis (RO) is Ultra-Pure Water Storage Ultra-Pure

the first major step used to remove contaminants 1 Tank Water (UPW)

& Air

from the mains water. Parker domnick hunter Vent Filter

filters are used prior to the RO systems to protect High-Purity

the RO membrane from large particles.

DI Water Oxidizer 3 Ion Solvents Isopropyl

Water

Ion exchange converts the post-RO water to UPW Exchange Alcohol (IPA)

O2

water with a combination of cation and anion Recycle

Rich Air

resins used to remove positive and negative ions. 4 High-Purity

Filters are used to remove any particles that Acids & Bases

Storage Hydrogenator Hydrouoric Acid

Ultrapure DI Water could come off the ion exchange resin beds.

Aquesous HF Core Filter(s) Location Purpose Features Benefits Advantages

Anhydrous HF Distillation Hydrogen Final filters may be used for last chance particle Abso-Mate High-Purity

Final

Solvent

capture from the system to ensure the very best

Hydrouoric Acid Incoming mains Polypropylene Capture large particles Protection of reverse

Acids & Bases

Purication

Hydrogen Peroxide

Concentrated UPW quality. Poly-Mate Sulfuric Acid

Aqueous HF Post RO, most filters used are hydrophilic with Poly-Mate Plus 1 water & pre-RO depth media in raw materials osmosis system High-Purity

Liquid

Extractor

a polypropylene structure. It’s important to

Polyflow

Hydrogen Peroxide

Anthraquinone note that some companies may decide to use Polyflow-G Acids & Bases

all-fluoropolymer filters if they use an aggressive

+ Solvent

line sanitization method, like ozone, to kill any Proflow II-E

bacteria in the line. Purication 2 Storage tank Hydrophobic PTFE Venting of air Prevent unwanted

Purication

Column 2 Column 1 Proflow II-E Select air vent membrane pressure buildup Services

Clariflow-WE Post ion Hydrophilic PES Capture fine Protect downstream

*UPW refers to ultra-pure deionized water used Clariflow-E 3 exchange resin membrane particles coming off equipment and

in Microelectronics manufacturing capture (no wetting needed) ion exchange beds added process

Clariflow-E Select

Clariflow-E Final Hydrophilic PES Tightest particle removal Final filtration step Selection Matrix

4 membrane to help meet final

Clariflow-E Select filtration step (no wetting needed) to meet UPW standards particle specification

Product Overview

| 5