Page 10 - Parker - High purity chemicals in electronic application

P. 10

Absorber

Column

High-Purity Acids & Bases Dilution DI Water Introduction

Acid

Storage 2

Sulfuric Acid Tank 3

Distillation

Schematic

Distillation Purier 4

Column

Sulfuric acid is highly used with either hydrogen

Hydrolyzer Sulfur Trioxide

UHP Sulfuric Acid

peroxide or ozonated UPW to create an intended Vaporizer

exothermic reaction. The added energy to this Liquid Selection Process

Isopropyl Alcohol

aggressive acid is ideal for removing hard-baked Sulfur Trioxide 4 Degasication

Storage Tank

Absorber photoresists and most organic contaminants Storage & Air Vent Filter

from the surface of silicon production wafers. Sulfur Trioxide

Sulfate Condensor UV

Esters Station

A common method of creating sulfuric acid 1 Sulfur Trioxide Applications

begins by mixing oleum and steam to produce Evaporator

Reverse

sulfur trioxide vapor. Filters may be used to 5 Osmosis Ultra-Pure

remove large particles and provide protection System 2 Water (UPW)

to the evaporator.

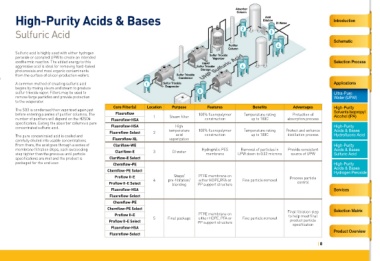

DI Water Core Filter(s) Location Purpose Features Benefits Reverse Advantages

Osmosis

Propene The SO3 is condensed then vaporized again just System 1 High-Purity

before entering a series of purifier columns. The Fluoroflow 1 Steam filter 100% fluoropolymer Temperature rating Protection of Solvents Isopropyl EDI

Alcohol (IPA)

up to 180C

number of purifiers will depend on the H2SO4 Fluoroflow-HSA construction Pretreatment absorption process

specification. Exiting the absorber column is pure Tank

Sulfuric concentrated sulfuric acid. Ultapure Fluoroflow-HSA High High-Purity Ion

Acid Dilute HF 2 temperature 100% fluoropolymer Temperature rating Protect and enhance Acids & Bases Exchange

Fluoroflow-Select

The pure concentrated acid is cooled and acid construction up to 180C distillation process Hydrouoric Acid

carefully diluted into usable concentrations. Fluoroflow-XL vaporization Ultra-Pure Water Storage

Tank

From there, the acid goes through a series of Clariflow-WE High-Purity

& Air

membrane filtration steps, each succeeding Hydrophilic PES Removal of particles in Provide consistent Acids & Bases

Vent Filter

step tighter than the previous until particle Clariflow-E 3 DI water membrane UPW down to 0.02 microns source of UPW Sulfuric Acid

specifications are met and the product is Clariflow-E Select

DI Water Oxidizer Ion

packaged for the end user. Chemflow-PE Water Exchange High-Purity

O2

Chemflow-PE Select Rich Air Recycle Acids & Bases

Hydrogen Peroxide

Proflow II-E Stage/ PTFE membrane on Process particle

Storage Proflow II-E Select 4 pre-filtration/ either HDPE,PFA or Fine particle removal control

Hydrogenator

Ultrapure DI Water blending PP support structure

Aquesous HF Fluoroflow-HSA Services

Anhydrous HF Distillation Hydrogen Purication

Final

Fluoroflow-Select

Solvent

Hydrogen Peroxide

Concentrated Chemflow-PE

Aqueous HF Hydrouoric Acid Chemflow-PE Select PTFE membrane on Final filtration step Selection Matrix

Liquid

Extractor

Proflow II-E

either HDPE, PFA or

product particle

Anthraquinone Proflow II-E Select 5 Final package PP support structure Fine particle removal to help meet final

+ Solvent specification

Fluoroflow-HSA

Fluoroflow-Select Purication Purication Product Overview

Column 2

Column 1

| 8