Page 6 - Parker - High purity chemicals in electronic application

P. 6

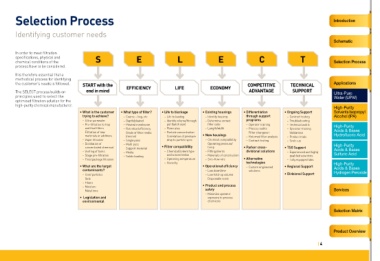

Selection Process Introduction

Identifying customer needs

Schematic

In order to meet filtration

specifications, physical and S E L E C T

chemical conditions of the Selection Process

process have to be considered.

It is therefore essential that a

methodical process for identifying

the customer’s needs is followed. START with the COMPETITIVE TECHNICAL Applications

The SELECT process builds on end in mind EFFICIENCY LIFE ECONOMY ADVANTAGE SUPPORT Ultra-Pure

principles used to select the Water (UPW)

optimized filtration solution for the

high-purity chemical manufacturer.

High-Purity

• What is the customer • What type of filter? • Life to blockage • Existing housings • Differentiation • Ongoing Support Solvents Isopropyl

trying to achieve? – Coarse – bag, etc – Life to loading – Identify housing through support – Contract testing Alcohol (IPA)

– Ultra-purewater – Depth/pleated – Identify volume/through – Determine correct programs – Troubleshooting

– Pre-filtration to trap – Pleated membrane put (batch size) filter code – Operator training – Technical audits High-Purity

and final filters – Retention/efficiency – Flow rates – Length/width – Process audits – Operator training Acids & Bases

– Filtration of raw – Grade of filter media – Particle concentration – Filter changeout – Validations

materials or additives (micron) – Correlation of pressure • New housings – Returned filter analysis – Product trials Hydrouoric Acid

– Vapor filtration – Single pass drop to particle spec – Chemical compatibility – Contract testing – Scale-up

– Distillation of – Multi pass – Operating pressure/ High-Purity

concentrated chemical – Support material • Filter compatibility temp • Parker cross- • TSG Support Acids & Bases

– Venting of tanks – Media – Chemical/solvent type – Fittings/vents divisional solutions – Experienced and highly

– Stage pre-filtration – Solids loading and concentration – Materials of construction qualified scientists Sulfuric Acid

– Final package filtration – Operating temperature – Size–flow rate • Alternative – Fully equipped labs

– Viscosity technologies High-Purity

• What are the target • Operational efficiency – Custom engineered • Regional Support

contaminants? – Low downtime solutions Acids & Bases

Hydrogen Peroxide

– Hard particles – Low hold-up volume • Divisional Support

– Gels – Disposable costs

– Fibers

– Moisture • Product and process

– Metal ions safety Services

– Minimize operator

• Legislation and exposure to process

environmental chemicals

Selection Matrix

Product Overview

| 4