Page 242 - Mechatronics with Experiments

P. 242

228 MECHATRONICS

I/O

Clock Peripherals

u(t) y(t)

PWM Actuators Process

PWM

signal

CPU

x = f(x,u)

u =.......

Timer Sensors

PWM

signal

Digital controller

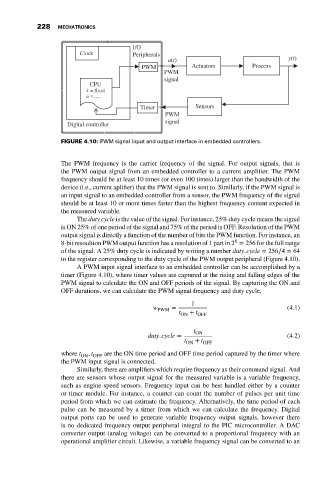

FIGURE 4.10: PWM signal input and output interface in embedded controllers.

The PWM frequency is the carrier frequency of the signal. For output signals, that is

the PWM output signal from an embedded controller to a current amplifier. The PWM

frequency should be at least 10 times (or even 100 times) larger than the bandwidth of the

device (i.e., current aplifier) that the PWM signal is sent to. Similarly, if the PWM signal is

an input signal to an embedded controller from a sensor, the PWM frequency of the signal

should be at least 10 or more times faster than the highest frequency content expected in

the measured variable.

The duty cycle is the value of the signal. For instance, 25% duty cycle means the signal

is ON 25% of one period of the signal and 75% of the period is OFF. Resolution of the PWM

output signal is directly a function of the number of bits the PWM function. For instance, an

8

8-bit resoultion PWM output function has a resolution of 1 part in 2 = 256 for the full range

of the signal. A 25% duty cycle is indicated by writing a number duty cycle = 256∕4 = 64

to the register corresponding to the duty cycle of the PWM output peripheral (Figure 4.10).

A PWM input signal interface to an embedded controller can be accomplished by a

timer (Figure 4.10), where timer values are captured at the rising and falling edges of the

PWM signal to calculate the ON and OFF periods of the signal. By capturing the ON and

OFF durations, we can calculate the PWM signal frequency and duty cycle,

1

w = (4.1)

PWM

t + t

ON OFF

t ON

duty cycle = (4.2)

t ON + t OFF

where t , t are the ON time period and OFF time period captured by the timer where

ON OFF

the PWM input signal is connected.

Similarly, there are amplifiers which require frequency as their command signal. And

there are sensors whose output signal for the measured variable is a variable frequency,

such as engine speed sensors. Frequency input can be best handled either by a counter

or timer module. For instance, a counter can count the number of pulses per unit time

period from which we can estimate the frequency. Alternatively, the time period of each

pulse can be measured by a timer from which we can calculate the frequency. Digital

output ports can be used to generate variable frequency output signals, however there

is no dedicated frequency output peripheral integral to the PIC microcontroller. A DAC

converter output (analog voltage) can be converted to a proportional frequency with an

operational amplifier circuit. Likewise, a variable frequency signal can be converted to an