Page 397 - Mechatronics with Experiments

P. 397

October 9, 2014 8:1

Printer: Yet to Come

JWST499-c06

JWST499-Cetinkunt

SENSORS 383 254mm×178mm

TABLE 6.1: RTD temperature sensor

materials and the resistance–

temperature sensitivity coefficient.

Material

Aluminum 0.00429

Copper 0.0043

Gold 0.004

Platinum 0.003927

Tungsten 0.0048

◦

RTDs may be used to measure the cryogenic temperature to approximately 700 C

temperature range. Platinum is one of the most common materials used in RTD sensors. The

main advantages of RTD sensors are that the resistance–temperature relationship is fairly

linear over a wide temperature range and the measurement accuracy can be as small as

◦

±0.005 C. Furthermore, the drift of the sensor over time is very small, typically in the range

◦

of less than 0.1 C∕year. As a result, RTDs do not require frequent calibration. A RTD is a

passive device. It has a resistance where the resistance changes linearly with temperature.

One good way of converting the change in resistance to voltage is to use the RTD in a

Wheatstone bridge circuit. The dynamic response of the RTD sensor is relatively slow

compared to other temperature sensors. RTDs can not be used to measure high frequency

transient temperature variations.

Thermistor Temperature Sensors Thermistor sensors are based on semicon-

ductor materials where the resistance of the sensing element reduces exponentially with

the temperature. The typical resistance and temperature relationship for a thermistor is

approximately,

( )

β 1 − 1

R = R ⋅ e T T o (6.175)

o

where is also a function of temperature and a property of the semiconductor material.

The variation in the resistance of a thermistor for a given temperature change is much

larger than the variation in resistance of a RTD sensor. This type of sensor is used for

their high sensitivity, high bandwidth, and ruggedness compared to RTDs. However, the

manufacturing variations in thermistors can be large from one sensor to another. Therefore,

they cannot be used as direct replacements to one another. As a result, each sensor must be

properly calibrated before replacement.

6.9.3 Thermocouples

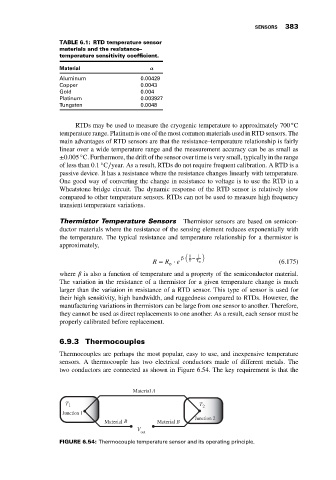

Thermocouples are perhaps the most popular, easy to use, and inexpensive temperature

sensors. A thermocouple has two electrical conductors made of different metals. The

two conductors are connected as shown in Figure 6.54. The key requirement is that the

Material A

T 1 T 2

Junction 1

Material B Material B Junction 2

V

out

FIGURE 6.54: Thermocouple temperature sensor and its operating principle.