Page 408 - Mechatronics with Experiments

P. 408

JWST499-Cetinkunt

JWST499-c06

394 MECHATRONICS Printer: Yet to Come October 9, 2014 8:1 254mm×178mm

6.12 VISION SYSTEMS

Vision systems, also called computer vision or machine vision, are general purpose sensors.

They are called the “smart sensors” in industry since what is sensed by a vision system

totally depends on the image processing software. A typical sensor is used to measure a

variable, that is temperature, pressure, length, and so on. A vision system can be used to

measure shape, orientation, area, defects, differences between parts, and so forth. Vision

technology has improved significantly over the past 20 years, to the extent that they are

rather standard “smart sensing components” in most factory automation systems for part

inspection and location detection. Their lower cost makes them increasingly attractive

for use in automated processes. Furthermore, vision systems are now standard in mobile

equipment safety systems to detect obstacles and avoid collisions, especially when used

with radar based obstacle detection systems.

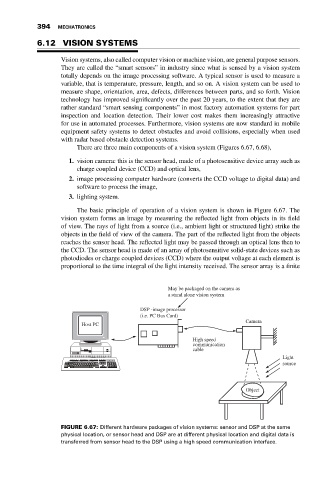

There are three main components of a vision system (Figures 6.67, 6.68),

1. vision camera: this is the sensor head, made of a photosensitive device array such as

charge coupled device (CCD) and optical lens,

2. image processing computer hardware (converts the CCD voltage to digital data) and

software to process the image,

3. lighting system.

The basic principle of operation of a vision system is shown in Figure 6.67. The

vision system forms an image by measuring the reflected light from objects in its field

of view. The rays of light from a source (i.e., ambient light or structured light) strike the

objects in the field of view of the camera. The part of the reflected light from the objects

reaches the sensor head. The reflected light may be passed through an optical lens then to

the CCD. The sensor head is made of an array of photosensitive solid-state devices such as

photodiodes or charge coupled devices (CCD) where the output voltage at each element is

proportional to the time integral of the light intensity received. The sensor array is a finite

May be packaged on the camera as

a stand alone vision system

DSP -image processor

(i.e. PC Bus Card)

Camera

Host PC

High speed

communication

cable

Light

source

Object

FIGURE 6.67: Different hardware packages of vision systems: sensor and DSP at the same

physical location, or sensor head and DSP are at different physical location and digital data is

transferred from sensor head to the DSP using a high speed communication interface.