Page 403 - Mechatronics with Experiments

P. 403

October 9, 2014 8:1

Printer: Yet to Come

JWST499-Cetinkunt

JWST499-c06

SENSORS 389 254mm×178mm

Measured

Pressure pressure Permanent pressure drop

drop caused by the sensor

P u

P

d

u d

P P

u d

Differential

pressure

sensor

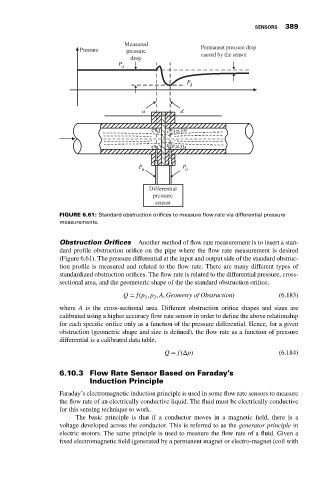

FIGURE 6.61: Standard obstruction orifices to measure flow rate via differential pressure

measurements.

Obstruction Orifices Another method of flow rate measurement is to insert a stan-

dard profile obstruction orifice on the pipe where the flow rate measurement is desired

(Figure 6.61). The pressure differential at the input and output side of the standard obstruc-

tion profile is measured and related to the flow rate. There are many different types of

standardized obstruction orifices. The flow rate is related to the differential pressure, cross-

sectional area, and the geometeric shape of the the standard obstruction orifice,

Q = f(p , p , A, Geometry of Obstruction) (6.183)

2

1

where A is the cross-sectional area. Different obstruction orifice shapes and sizes are

calibrated using a higher accuracy flow rate sensor in order to define the above relationship

for each specific orifice only as a function of the pressure differential. Hence, for a given

obstruction (geometric shape and size is defined), the flow rate as a function of pressure

differential is a calibrated data table,

Q = f(Δp) (6.184)

6.10.3 Flow Rate Sensor Based on Faraday’s

Induction Principle

Faraday’s electromagnetic induction principle is used in some flow rate sensors to measure

the flow rate of an electrically conductive liquid. The fluid must be electrically conductive

for this sensing technique to work.

The basic principle is that if a conductor moves in a magnetic field, there is a

voltage developed across the conductor. This is referred to as the generator principle in

electric motors. The same principle is used to measure the flow rate of a fluid. Given a

fixed electromagnetic field (generated by a permanent magnet or electro-magnet (coil with