Page 407 - Mechatronics with Experiments

P. 407

Printer: Yet to Come

October 9, 2014 8:1

JWST499-Cetinkunt

JWST499-c06

SENSORS 393 254mm×178mm

6.11 HUMIDITY SENSORS

Relative humidity is defined as the percentage ratio of the amount of water vapor in moist

air, versus the amount of water vapor in saturated air at a given temperature and pressure.

Relative humidity is strongly affected by temperature.

The main types of humidity sensors use the capacitance, resistive, and optical reflec-

tion principles in the transduction stage.

Capacitive humidity sensors use a polymer material which changes capacitance as

a function of humidity. The relationship is fairly linear. The sensor is designed as parallel

plates with porous electrodes on a substrate. The electrodes are coated with a dielectric

polymer material that absorbs water vapor from the environment with changes in humidity.

The resulting change in dielectric constant causes a variation in capacitance. The varia-

tion in capacitance is converted to voltage by an appropriate op-amp circuit to provide a

proportional voltage output.

Resistance based humidity sensors use materials on an electrode whose resistance

change as a function of humidity. In general, the resistance–humidity relationship is an

exponential relationship, and hence requires digital signal processing so that the voltage

output is proportional to the measured humidity. Capacitive humidity sensors are more

rugged and have less dependency on the temperature than the resistive humidity sensors.

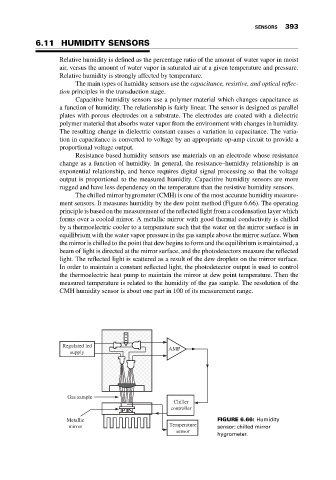

The chilled mirror hygrometer (CMH) is one of the most accurate humidity measure-

ment sensors. It measures humidity by the dew point method (Figure 6.66). The operating

principle is based on the measurement of the reflected light from a condensation layer which

forms over a cooled mirror. A metallic mirror with good thermal conductivity is chilled

by a thermoelectric cooler to a temperature such that the water on the mirror surface is in

equilibrium with the water vapor pressure in the gas sample above the mirror surface. When

the mirror is chilled to the point that dew begins to form and the equilibrium is maintained, a

beam of light is directed at the mirror surface, and the photodetectors measure the reflected

light. The reflected light is scattered as a result of the dew droplets on the mirror surface.

In order to maintain a constant reflected light, the photodetector output is used to control

the thermoelectric heat pump to maintain the mirror at dew point temperature. Then the

measured temperature is related to the humidity of the gas sample. The resolution of the

CMH humidity sensor is about one part in 100 of its measurement range.

Regulated led AMP

supply

Gas sample

Chiller

controller

Metallic FIGURE 6.66: Humidity

mirror Temperature sensor: chilled mirror

sensor

hygrometer.