Page 68 - GuardII+ Series 4208 Platform Flux User Manual

P. 68

Appendix

NOTE:

If the measurement status is consistently showing a value other than “2”,

this may indicate a problem. Refer to Section 7 for troubleshooting

instructions and/or consult Iris Power LP Technical Support for assistance.

For round-rotor machines, coils with more than 10 turns per coil typically show signs of a

problem when the coil-to-coil flux density differs by 3%. Round-rotor machine coils with less

than 10 turns per coil typically show signs of a problem when the coil-to-coil flux density differs

by 5% to 10%. For salient-pole machines, poles typically show signs of a problem when the

th

pole-to-pole flux density differs by 1% to 2%. Flux density is reported in 100 ’s of a percent;

so a value of -300 reported on Modbus on a salient-pole machine indicates a flux density drop

of 3%, and therefore a potential problem.

8.4. Modbus Slave Timing

NOTE:

As described in Section 4.2, GuardII+ updates the flux Modbus data

registers after every measurement cycle, which occurs every 30 minutes.;

so while the monitor can respond to Modbus requests very quickly, the

flux data simply will not change that often. Polling the monitor every few

seconds is just wasting network bandwidth.

Each monitoring technology in the GuardII+ Series 4208 Platform has its

own measurement cycle; so If the monitor has other monitoring

technologies installed, those other technologies may provide Modbus

updates more rapidly.

To achieve the best performance when polling GuardII+’s Modbus data registers, the

following configurations of the polling system should be used:

• Modbus response timeout should be set to no less than 6000ms

• Modbus polling should occur no more often than once per minute.

8.5. Using PLC-Style Addressing

GuardII+ uses protocol-style Modbus addressing (Base 0), not PLC-style Modbus

addressing (Base 1). When using PLC-style addressing to acquire Modbus data from

GuardII+, this will cause an address shift.

NOTE:

When accessing GuardII+ data registers using PLC-style addressing, the

address must be increased by 1.

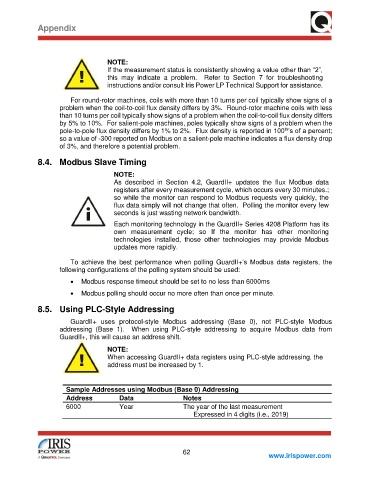

Sample Addresses using Modbus (Base 0) Addressing

Address Data Notes

6000 Year The year of the last measurement

Expressed in 4 digits (i.e., 2019)

62

www.irispower.com