Page 35 - february

P. 35

PROFESSIONAL ADVICE

a) b) c)

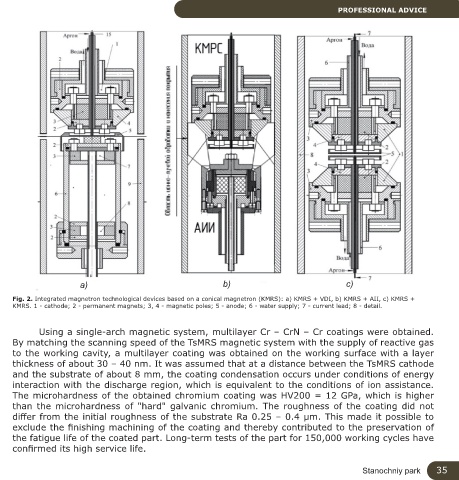

Fig. 2. Integrated magnetron technological devices based on a conical magnetron (KMRS): a) KMRS + VDI, b) KMRS + AII, c) KMRS +

KMRS. 1 - cathode; 2 - permanent magnets; 3, 4 - magnetic poles; 5 - anode; 6 - water supply; 7 - current lead; 8 - detail.

Using a single-arch magnetic system, multilayer Cr – CrN – Cr coatings were obtained.

By matching the scanning speed of the TsMRS magnetic system with the supply of reactive gas

to the working cavity, a multilayer coating was obtained on the working surface with a layer

thickness of about 30 – 40 nm. It was assumed that at a distance between the TsMRS cathode

and the substrate of about 8 mm, the coating condensation occurs under conditions of energy

interaction with the discharge region, which is equivalent to the conditions of ion assistance.

The microhardness of the obtained chromium coating was HV200 = 12 GPa, which is higher

than the microhardness of "hard" galvanic chromium. The roughness of the coating did not

differ from the initial roughness of the substrate Ra 0.25 – 0.4 μm. This made it possible to

exclude the finishing machining of the coating and thereby contributed to the preservation of

the fatigue life of the coated part. Long-term tests of the part for 150,000 working cycles have

confirmed its high service life.

Stanochniy park 35