Page 25 - June

P. 25

METALWORKING EQUIPMENT AND TOOLS

chief mechanic's departments at our machine-building enterprises, that is, specifically those

who directly have to control the technical state of any mechanism (unit) consisting of registered

with OGM. In addition, if the reason was not this, then any more or less competent mechanic

at the enterprise would easily make an accurate diagnosis of an excessively lumbering and

vibrating industrial vacuum cleaner.

In factories where industrial vacuum cleaners are manufactured (assembled), drive

motors are not produced. They are supplied from another manufacturer, who (according to

technology) is simply obliged to test their finished products. Therefore, a rotor-shaft-shaft of

a new electric motor, poorly installed in the stator

а housing, would immediately show its inconsistency

with the technical parameters, which exclude any

imbalance relative to the stator. Thus, an enterprise

that manufactures (collects) the finished product

(industrial vacuum cleaners) receives from its

subcontractor electric motors, already checked

and accepted by the manufacturer's quality control

department. It remains only to install and fix the

impeller with "blades" on the shaft-rotor of the

electric motor. Again, according to the technology,

the fan impeller after manufacturing is subjected to

static balancing and the imbalance is eliminated by

milling, that is, by the method of removing metal

in its individual sectors. Further, the ventilation

unit (industrial vacuum cleaner) is completely

b

б assembled and in finished form is subjected to a

factory test.

The test result is usually positive. New,

correctly installed bearings on the shaft-rotor of

the electric motor also have that not wasted margin

of safety, which allows the impeller, mounted on

the shaft, to maintain a stable geometry at high

speeds of its rotation. Then the finished product is

sent to the consumer.

What is the fate of these industrial vacuum

cleaners in industrial conditions we already know.

They regularly catch abrasive dust in production

facilities from working sharpeners. They work for a

year, two ... five years, until external negative signs

begin to manifest themselves: excessive noise and

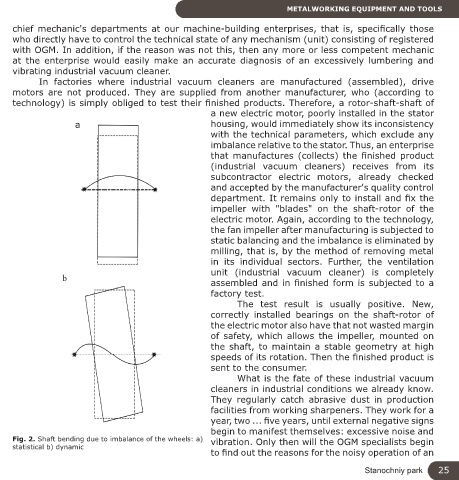

Fig. 2. Shaft bending due to imbalance of the wheels: a) vibration. Only then will the OGM specialists begin

statistical b) dynamic

to find out the reasons for the noisy operation of an

Stanochniy park 25