Page 38 - June

P. 38

METALWORKING EQUIPMENT AND TOOLS

technically stable. Oscillations corresponding to such an attractor are self-oscillations, but their

amplitude can satisfy the requirements for technical stability.

However, the cutting process considered in the phase space for a frequency range including

one of the natural frequencies may correspond not to one quasi-attractor, but two. The transition

of the cutting system from one technically stable attractor to another leads to intense self-

oscillations. The attractor accompanying intense self-oscillations usually deviates significantly

from the tangential direction and in the XY plane is elongated in a direction close to the normal

to the cutting surface. It has a scope that is several times greater than the requirements for

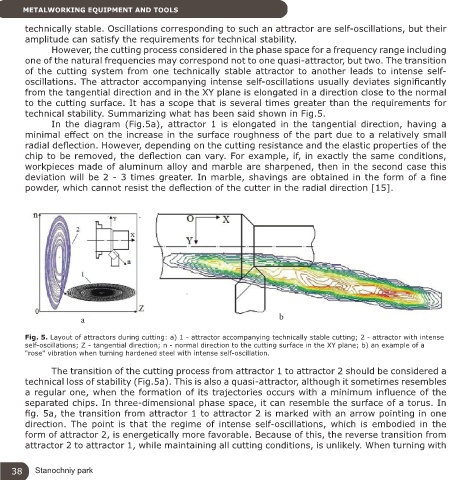

technical stability. Summarizing what has been said shown in Fig.5.

In the diagram (Fig.5a), attractor 1 is elongated in the tangential direction, having a

minimal effect on the increase in the surface roughness of the part due to a relatively small

radial deflection. However, depending on the cutting resistance and the elastic properties of the

chip to be removed, the deflection can vary. For example, if, in exactly the same conditions,

workpieces made of aluminum alloy and marble are sharpened, then in the second case this

deviation will be 2 - 3 times greater. In marble, shavings are obtained in the form of a fine

powder, which cannot resist the deflection of the cutter in the radial direction [15].

a b

Fig. 5. Layout of attractors during cutting: a) 1 - attractor accompanying technically stable cutting; 2 - attractor with intense

self-oscillations; Z - tangential direction; n - normal direction to the cutting surface in the XY plane; b) an example of a

"rose" vibration when turning hardened steel with intense self-oscillation.

The transition of the cutting process from attractor 1 to attractor 2 should be considered a

technical loss of stability (Fig.5a). This is also a quasi-attractor, although it sometimes resembles

a regular one, when the formation of its trajectories occurs with a minimum influence of the

separated chips. In three-dimensional phase space, it can resemble the surface of a torus. In

fig. 5a, the transition from attractor 1 to attractor 2 is marked with an arrow pointing in one

direction. The point is that the regime of intense self-oscillations, which is embodied in the

form of attractor 2, is energetically more favorable. Because of this, the reverse transition from

attractor 2 to attractor 1, while maintaining all cutting conditions, is unlikely. When turning with

38 Stanochniy park