Page 52 - June

P. 52

PROFESSIONAL ADVICE

As already mentioned, scheduled periodic maintenance of compressors by regular

mechanics-repairmen at our machine-building enterprises is rarely carried out anywhere. It is

not the repair of the compressor (due to a breakdown), but its scheduled preventive maintenance

(SPM). This attitude to compressors originates from the established principle in our reality: "do

not interfere with the machine to work." In addition, production managers, as a rule, relieve

themselves of the burden of responsibility for organizing the auxiliary equipment SPM, placing

this responsibility on the department of the chief mechanic (DCM) of the enterprise. At the

same time, the above managers do not provide DCM repair specialists with the opportunity to

"approach" the compressors during working hours on weekdays, when they are busy pumping

air for the main production. Only the weekend remains. However, you have to pay for work on

weekends. But paying "overtime" for supposedly "routine" maintenance of ancillary equipment

is something incredible. Moreover, if this equipment seems to be working properly. Well, why

should he "interfere" with this?

Below I present to the readers my version of the periodic maintenance of the SPINN series

compressors, taking into account the requirements of the original guidelines. And, contrary to

our production practice, the main time of work on the compressor application software in the

shown version falls on weekends and holidays. Let the DCM repair specialists not condemn me.

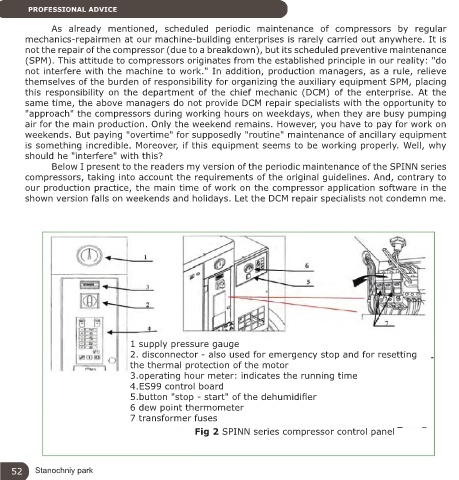

1 supply pressure gauge

2. disconnector - also used for emergency stop and for resetting

the thermal protection of the motor

3.operating hour meter: indicates the running time

4.ES99 control board

5.button "stop - start" of the dehumidifier

6 dew point thermometer

7 transformer fuses

Fig 2 SPINN series compressor control panel

52 Stanochniy park