Page 38 - Flip IOCL Book.cdr

P. 38

Root Cause

Tube leakage was due to thermal induced cracking during start-up.

Recommendations

1. The reformer heating rate shall be maintained as per recommendation of process licensor (max 50 C/hr).

The operating manual shall be revised and opinion of licensor may be sought.

2. Reformer section feed cut-in to be done with by-pass CV of the main feed control valve and after

stabilization main CV to be taken in line.

3. Leaky jacket line of fuel naphtha to be replaced/rectified.

4. Monitoring of furnace during start-up/shutdown.

5. Installation of TFM may be explored for furnace online monitoring.

Case 16 Date: 20.01.2020 Time: 16:00 hrs.

Incident

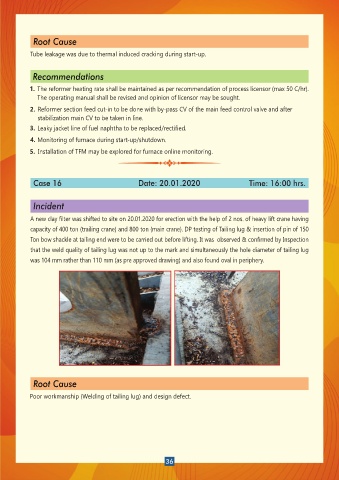

A new clay filter was shifted to site on 20.01.2020 for erection with the help of 2 nos. of heavy lift crane having

capacity of 400 ton (trailing crane) and 800 ton (main crane). DP testing of Tailing lug & insertion of pin of 150

Ton bow shackle at tailing end were to be carried out before lifting. It was observed & confirmed by Inspection

that the weld quality of tailing lug was not up to the mark and simultaneously the hole diameter of tailing lug

was 104 mm rather than 110 mm (as pre approved drawing) and also found oval in periphery.

Root Cause

Poor workmanship (Welding of tailing lug) and design defect.

36