Page 13 - February 2021 Track N Times

P. 13

TECHNICAL TRAINING

Dust System Continued

run. Sometimes repeating the above will free the rotor up and you’ll be back

in business. If it still doesn’t run or is running very noisy, it is best you unin-

stall the rotary valve completely and order a new one #203267. The rotary

valves have had an ECR approved to add bearing guards, as the most com-

mon failure is the non-drive end bearing getting damaged from the grind

dust.

Now that the rotary valve is running or removed, we can work on the au-

ger. Again, flip on the disconnect switch while observing the motor fan. If the

auger runs, let it be and check back on it in an hour. If you notice no move-

ment, check the breaker again, if tripped you will need to troubleshoot if the

breaker, contactor, wiring or motor is bad. If auger attempts to run and

stalls, turn disconnect back off, lock out and go to the other side of the ma-

chine. You will need to remove the bearing. Most bearings will not slide off

the shaft once the bolts are removed, and you will need a grinder with a cut

off disc. Cut the bearing horizontal to the shaft, being careful to not damage

the shaft more than necessary. Once cut ¾ way through, beat on the bear-

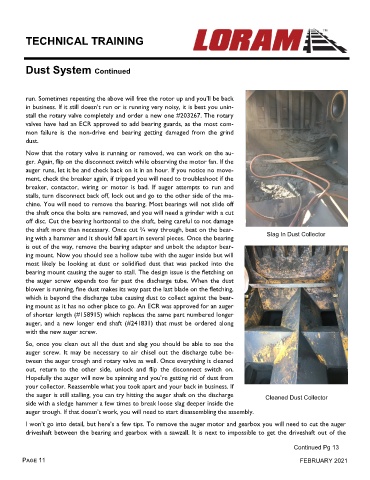

ing with a hammer and it should fall apart in several pieces. Once the bearing Slag In Dust Collector

is out of the way, remove the bearing adapter and unbolt the adaptor bear-

ing mount. Now you should see a hollow tube with the auger inside but will

most likely be looking at dust or solidified dust that was packed into the

bearing mount causing the auger to stall. The design issue is the fletching on

the auger screw expends too far past the discharge tube. When the dust

blower is running, fine dust makes its way past the last blade on the fletching,

which is beyond the discharge tube causing dust to collect against the bear-

ing mount as it has no other place to go. An ECR was approved for an auger

of shorter length (#158915) which replaces the same part numbered longer

auger, and a new longer end shaft (#241831) that must be ordered along

with the new auger screw.

So, once you clean out all the dust and slag you should be able to see the

auger screw. It may be necessary to air chisel out the discharge tube be-

tween the auger trough and rotary valve as well. Once everything is cleaned

out, return to the other side, unlock and flip the disconnect switch on.

Hopefully the auger will now be spinning and you’re getting rid of dust from

your collector. Reassemble what you took apart and your back in business. If

the auger is still stalling, you can try hitting the auger shaft on the discharge Cleaned Dust Collector

side with a sledge hammer a few times to break loose slag deeper inside the

auger trough. If that doesn’t work, you will need to start disassembling the assembly.

I won’t go into detail, but here’s a few tips. To remove the auger motor and gearbox you will need to cut the auger

driveshaft between the bearing and gearbox with a sawzall. It is next to impossible to get the driveshaft out of the

Continued Pg 13

Page 11 FEBRUARY 2021