Page 192 - Towards A Sustainable Future 2024

P. 192

Eco-Solutions

Our ESI team identified several areas for improvement in

the environmental performance of Starlight that augment

existing best practices.

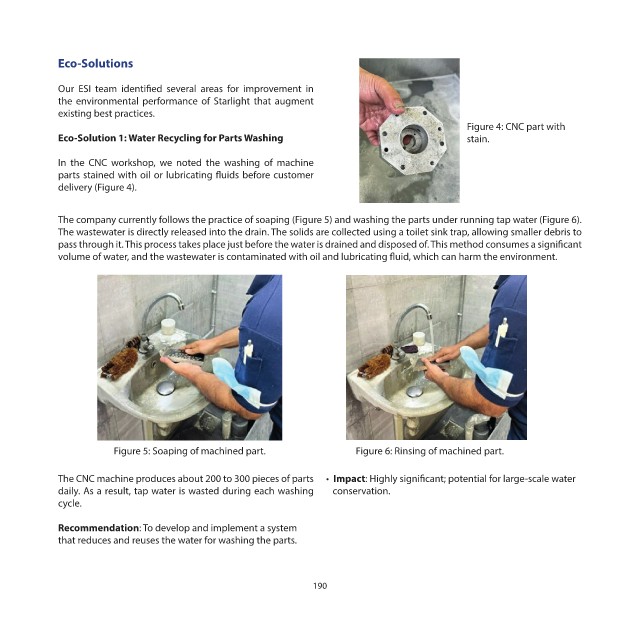

Figure 4: CNC part with

Eco-Solution 1: Water Recycling for Parts Washing stain.

In the CNC workshop, we noted the washing of machine

parts stained with oil or lubricating fluids before customer

delivery (Figure 4).

The company currently follows the practice of soaping (Figure 5) and washing the parts under running tap water (Figure 6).

The wastewater is directly released into the drain. The solids are collected using a toilet sink trap, allowing smaller debris to

pass through it. This process takes place just before the water is drained and disposed of. This method consumes a significant

volume of water, and the wastewater is contaminated with oil and lubricating fluid, which can harm the environment.

Figure 5: Soaping of machined part. Figure 6: Rinsing of machined part.

The CNC machine produces about 200 to 300 pieces of parts • Impact: Highly significant; potential for large-scale water

daily. As a result, tap water is wasted during each washing conservation.

cycle.

Recommendation: To develop and implement a system

that reduces and reuses the water for washing the parts.

190