Page 168 - Towards A Sustainable Future , Phase 3 2025, E-Book_Neat

P. 168

As such, using the information gathered, Table 1 below Methodology

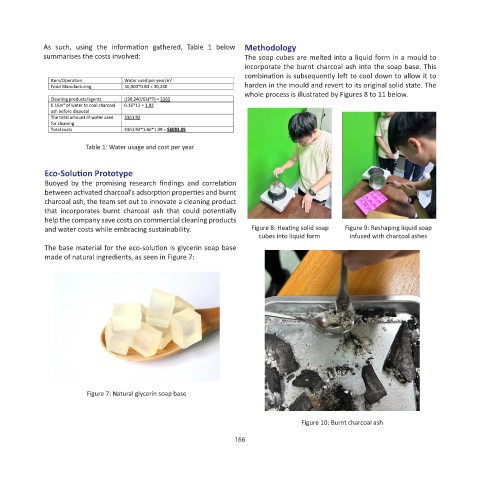

summarises the costs involved: The soap cubes are melted into a liquid form in a mould to

incorporate the burnt charcoal ash into the soap base. This

combination is subsequently left to cool down to allow it to

harden in the mould and revert to its original solid state. The

whole process is illustrated by Figures 8 to 11 below.

Table 1: Water usage and cost per year

Eco-Solution Prototype

Buoyed by the promising research findings and correlation

between activated charcoal's adsorption properties and burnt

charcoal ash, the team set out to innovate a cleaning product

that incorporates burnt charcoal ash that could potentially

help the company save costs on commercial cleaning products

and water costs while embracing sustainability. Figure 8: Heating solid soap Figure 9: Reshaping liquid soap

cubes into liquid form infused with charcoal ashes

The base material for the eco-solution is glycerin soap base

made of natural ingredients, as seen in Figure 7:

Figure 7: Natural glycerin soap base

Figure 10: Burnt charcoal ash

166