Page 1151 - Workshop Manual - Aumark (BJ1051)

P. 1151

51-59

Heater and AC- AC compressor

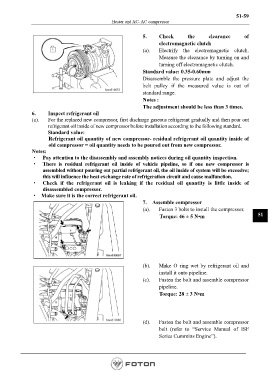

5. Check the clearance of

electromagnetic clutch

(a). Electrify the electromagnetic clutch.

Measure the clearance by turning on and

turning off electromagnetic clutch.

Standard value: 0.35-0.60mm

Disassemble the pressure plate and adjust the

belt pulley if the measured value is out of

standard range.

Notes :

The adjustment should be less than 3 times.

6. Inspect refrigerant oil

(a). For the replaced new compressor, first discharge gaseous refrigerant gradually and then pour out

refrigerant oil inside of new compressor before installation according to the following standard.

Standard value:

Refrigerant oil quantity of new compressor- residual refrigerant oil quantity inside of

old compressor = oil quantity needs to be poured out from new compressor.

Notes:

· Pay attention to the disassembly and assembly notices during oil quantity inspection.

· There is residual refrigerant oil inside of vehicle pipeline, so if one new compressor is

assembled without pouring out partial refrigerant oil, the oil inside of system will be excessive;

this will influence the heat exchange rate of refrigeration circuit and cause malfunction.

· Check if the refrigerant oil is leaking if the residual oil quantity is little inside of

disassembled compressor.

· Make sure it is the correct refrigerant oil.

7. Assemble compressor

(a). Fasten 3 bolts to install the compressor.

Torque: 46 ± 5 N•m 51

(b). Make O ring wet by refrigerant oil and

install it onto pipeline.

(c). Fasten the bolt and assemble compressor

pipeline.

Torque: 28 ± 3 N•m

(d). Fasten the bolt and assemble compressor

belt (refer to “Service Manual of ISF

Series Cummins Engine”).

Page 1151