Page 735 - Workshop Manual - Aumark (BJ1051)

P. 735

25-25

Rear axle- Differential assembly

Inspection

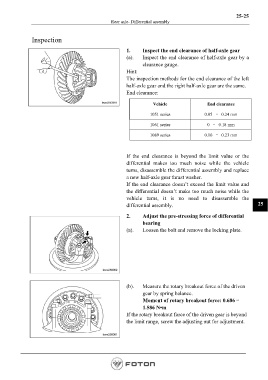

1. Inspect the end clearance of half-axle gear

(a). Inspect the end clearance of half-axle gear by a

clearance gauge.

Hint:

The inspection methods for the end clearance of the left

half-axle gear and the right half-axle gear are the same.

End clearance:

Vehicle End clearance

1051 series 0.05 ~ 0.24 mm

1061 series 0 ~ 0.18 mm

1089 series 0.10 ~ 0.23 mm

If the end clearance is beyond the limit value or the

differential makes too much noise while the vehicle

turns, disassemble the differential assembly and replace

a new half-axle gear thrust washer.

If the end clearance doesn’t exceed the limit value and

the differential doesn’t make too much noise while the

vehicle turns, it is no need to disassemble the

differential assembly. 25

2. Adjust the pre-stressing force of differential

bearing

(a). Loosen the bolt and remove the locking plate.

(b). Measure the rotary breakout force of the driven

gear by spring balance.

Moment of rotary breakout force: 0.686~

1.586 N•m

If the rotary breakout force of the driven gear is beyond

the limit range, screw the adjusting nut for adjustment.

Page 735