Page 48 - POSTER FYP MAC-OGOS 2025

P. 48

A SIMULATION STUDY ON QUEUING SYSTEM OPTIMIZATION AT UNIVERSITI

PUTRA MALAYSIA (UPM) CAFETERIA USING ARENA SOFTWARE

NUR HIDAYAH BINTI HALIM (K242/49)

SUPERVISOR: AIMI ZULLIAYANA BINTI ROSLI

ABSTRACT PROLEM STATEMENT

This study investigates the queuing system at the Faculty of Engineering The Faculty of Engineering cafeteria at Universiti Putra Malaysia faces

cafeteria, UPM, where long waiting times during peak hours negatively significant queuing issues during peak lunch hours. Customers arrive from

affect service efficiency and customer satisfaction. Using Arena multiple directions without a proper line, leading to crowding, confusion,

Simulation Software, a discrete-event model was developed to represent and extended waiting times. A single staff member is responsible for both

the current system and evaluate a proposed improvement. The proposed serving rice and managing payments, creating service delays and

model introduces a self-service rice station and a structured single-line bottlenecks. These inefficiencies not only reduce customer satisfaction but

queue to streamline customer flow without requiring additional staff or

costs. Simulation results showed that the average time spent in the system may also result in customers leaving the queue before being served. There

was reduced from 3.84 minutes to 2.71 minutes, representing a 29.51 is a need to improve the system to reduce waiting time and enhance service

percent improvement. The findings demonstrate that simple layout and flow without increasing operational costs or hiring additional staff.

process changes can significantly enhance queuing performance, making

the cafeteria more efficient and customer-friendly.

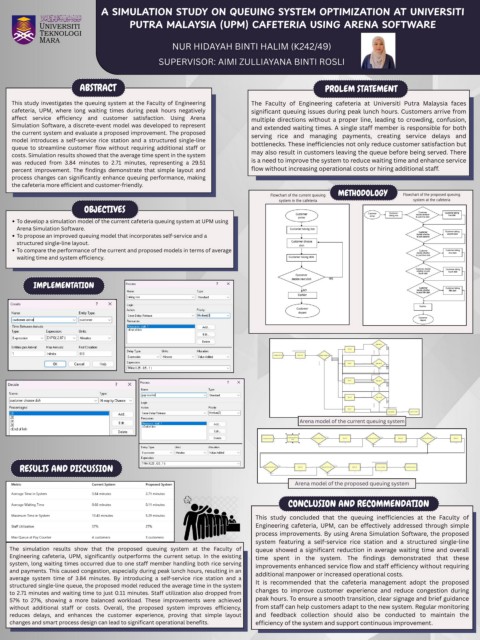

METHODOLOGY

Flowchart of the current queuing Flowchart of the proposed queuing

system in the cafeteria system at the cafeteria

OBJECTIVES

To develop a simulation model of the current cafeteria queuing system at UPM using

Arena Simulation Software.

To propose an improved queuing model that incorporates self-service and a

structured single-line layout.

To compare the performance of the current and proposed models in terms of average

waiting time and system efficiency.

IMPLEMENTATION

Arena model of the current queuing system

RESULTS AND DISCUSSION

Arena model of the proposed queuing system

CONCLUSION AND RECOMMENDATION

This study concluded that the queuing inefficiencies at the Faculty of

Engineering cafeteria, UPM, can be effectively addressed through simple

process improvements. By using Arena Simulation Software, the proposed

system featuring a self-service rice station and a structured single-line

The simulation results show that the proposed queuing system at the Faculty of queue showed a significant reduction in average waiting time and overall

Engineering cafeteria, UPM, significantly outperforms the current setup. In the existing time spent in the system. The findings demonstrated that these

system, long waiting times occurred due to one staff member handling both rice serving improvements enhanced service flow and staff efficiency without requiring

and payments. This caused congestion, especially during peak lunch hours, resulting in an additional manpower or increased operational costs.

average system time of 3.84 minutes. By introducing a self-service rice station and a

structured single-line queue, the proposed model reduced the average time in the system It is recommended that the cafeteria management adopt the proposed

to 2.71 minutes and waiting time to just 0.11 minutes. Staff utilization also dropped from changes to improve customer experience and reduce congestion during

57% to 27%, showing a more balanced workload. These improvements were achieved peak hours. To ensure a smooth transition, clear signage and brief guidance

without additional staff or costs. Overall, the proposed system improves efficiency, from staff can help customers adapt to the new system. Regular monitoring

reduces delays, and enhances the customer experience, proving that simple layout and feedback collection should also be conducted to maintain the

changes and smart process design can lead to significant operational benefits. efficiency of the system and support continuous improvement.