Page 369 - Programmable Logic Controllers, Fifth Edition - Mobile version

P. 369

Monitor Tags window, when the motor is operating. When

ward contactor coil is connected in series with the

the motor is operating: • The normally closed contact controlled by the for-

reverse coil.

• The XIC Motor_Start instruction is false because

the NO start button is open; therefore its value is 0. • The normally closed contact controlled by the

• The XIC Motor_Stop instruction is true because the reverse contactor coil is connected in series with the

NC stop button is closed; therefore its value is 1. forward coil.

• The OTE Motor_Run instruction is true because the • When the forward coil is energized, the normally

rung has logic continuity; therefore its value is 1. closed contact in series with the reverse coil is

opened to prevent the reverse coil from being

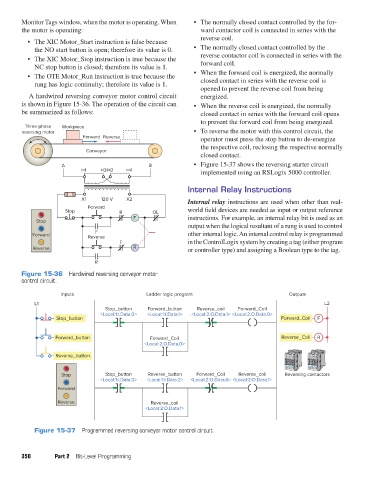

A hardwired reversing conveyor motor control circuit energized.

is shown in Figure 15-36. The operation of the circuit can • When the reverse coil is energized, the normally

be summarized as follows: closed contact in series with the forward coil opens

to prevent the forward coil from being energized.

Three-phase Workpiece

reversing motor • To reverse the motor with this control circuit, the

Forward Reverse operator must press the stop button to de-energize

the respective coil, reclosing the respective normally

Conveyor

closed contact.

A B • Figure 15-37 shows the reversing starter circuit

H1 H3H2 H4 implemented using an RSLogix 5000 controller.

Internal Relay Instructions

X1 120 V X2 Internal relay instructions are used when other than real-

Forward

Stop R OL world field devices are needed as input or output reference

F instructions. For example, an internal relay bit is used as an

Stop

output when the logical resultant of a rung is used to control

F

Forward Reverse other internal logic. An internal control relay is programmed

F in the ControlLogix system by creating a tag (either program

Reverse R or controller type) and assigning a Boolean type to the tag.

R

Figure 15-36 Hardwired reversing conveyor motor

control circuit.

Inputs Ladder logic program Outputs

L1 L2

Stop_button Forward_button Reverse_coil Forward_Coil

<Local:1:I.Data.0> <Local:1:I.Data.1> <Local:2:O.Data.1> <Local:2:O.Data.0>

Stop_button Forward_Coil F

Forward_button Forward_Coil Reverse_Coil R

<Local:2:O.Data.0>

Reverse_button

Stop Stop_button Reverse_button Forward_Coil Reverse_coil Reversing contactors

<Local:1:I.Data.0> <Local:1:I.Data.2> <Local:2:O.Data.0> <Local:2:O.Data.1>

Forward

Reverse Reverse_coil

<Local:2:O.Data.1>

Figure 15-37 Programmed reversing conveyor motor control circuit.

350 Part 2 Bit-Level Programming

pet73842_ch15_333-394.indd 350 03/11/15 7:33 PM