Page 117 - Buy Premium Tools ATORN Catalogue

P. 117

Reaming tools

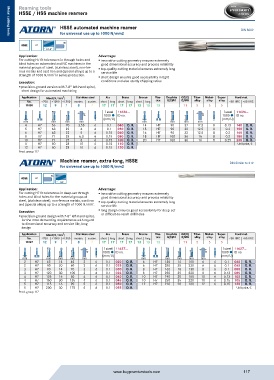

HSSE / HSS machine reamers

HSSE automated machine reamer DIN 8089

for universal use up to 1000 N/mm2

Metal cutting tools

Metal cutting tools

HA

HSSE

7–8°

Application: Advantage:

For cutting H7 fit tolerances in through holes and innovative cutting geometry ensures extremely

blind holes on automated and NC machines in the good dimensional accuracy and process reliability

material groups of steel, (stainless steel), non-fer- top-quality cutting material ensures extremely long

rous metals and cast iron and (special alloys) up to a service life

strength of 1000 N/mm in series production.

2

short design ensures good accessibility in tight

Execution: conditions and also sturdy chipping ratios

precision-ground version with 7-8° left-hand spiral,

short design for automated machining

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11626 12 9 7 8 7 17 17 17 17 13 13 13 11 5 5 5

f steel 11626... f steel 11626...

h6 1000 ID no. h6 1000 ID no.

(mm/U) (mm/U)

mm mm mm mm mm mm mm mm

4 H7 56 20 3.55 6 0.1 040 O. R. 14 H7 90 32 12.5 8 0.15 140 O. R.

5 H7 63 22 4 6 0.1 050 O. R. 15 H7 90 32 12.5 8 0.2 150 O. R.

6 H7 63 22 5 6 0.15 060 O. R. 16 H7 90 32 12.5 8 0.2 160 O. R.

8 H7 71 25 6.3 6 0.15 080 O. R. 18 H7 100 36 16 8 0.2 180 O. R.

10 H7 71 25 8 6 0.15 100 O. R. 20 H7 100 36 16 8 0.25 200 O. R.

11 H7 80 28 10 6 0.15 110 O. R. Unit price, €

12 H7 80 28 10 6 0.15 120 O. R.

Prod. group 117

Machine reamer, extra-long, HSSE DIN Similar to 212

for universal use up to 1000 N/mm2

HA

HSSE

10°

Application: Advantage:

For cutting H7 fit tolerances in deep-set through innovative cutting geometry ensures extremely

holes and blind holes for the material groups of good dimensional accuracy and process reliability

steel, (stainless steel), non-ferrous metals, cast iron top-quality cutting material ensures extremely long

and (special alloys) up to a strength of 1000 N/mm . 2 service life

Execution: long design ensures good accessibility for deep-set

precision-ground design with 7-8° left-hand spiral, or difficult-to-reach drill holes

for the most demanding requirements with regard

to dimensional accuracy and service life, long

design

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11627 12 9 7 8 7 17 17 17 17 13 13 13 11 5 5 5

f steel 11627... f steel 11627...

h6 1000 ID no. h6 1000 ID no.

(mm/U) (mm/U)

mm mm mm mm mm mm mm mm mm mm

2 H7 65 14 45 2 6 0.1 020 O. R. 6 H7 130 16 100 6 6 0.1 060 O. R.

2 H7 80 20 60 2 6 0.1 025 O. R. 6 H7 250 35 220 6 6 0.1 065 O. R.

3 H7 90 14 70 3 6 0.1 030 O. R. 8 H7 160 18 130 8 6 0.1 080 O. R.

3 H7 120 30 100 3 6 0.1 035 O. R. 8 H7 250 35 220 8 6 0.13 085 O. R.

4 H7 105 16 80 4 6 0.1 040 O. R. 10 H7 190 20 150 10 6 0.13 100 O. R.

4 H7 160 30 135 4 6 0.1 045 O. R. 10 H7 250 35 220 10 6 0.15 105 O. R.

5 H7 115 16 90 5 6 0.1 050 O. R. 12 H7 210 20 160 12 6 0.15 120 O. R.

5 H7 200 30 175 5 6 0.1 055 O. R. Unit price, €

Prod. group 117

www.buypremiumtools.com 117