Page 475 - 2006 HARLEY FLSTCI SERVICE MANUAL

P. 475

B.4 PART NO. 70585-93 70586-93 70587-93

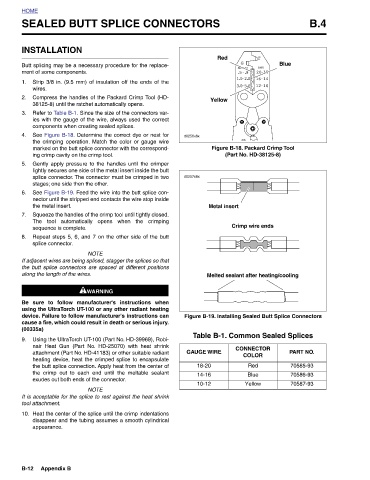

Figure B-18. Packard Crimp Tool (Part No. HD-38125-8) Crimp wire ends Melted sealant after heating/cooling Figure B-19. Installing Sealed Butt Splice Connectors Table B-1. Common Sealed Splices CONNECTOR COLOR Red Blue Yellow

Blue

Red Yellow Metal insert

d0256x8x d0257x8x GAUGE WIRE 18-20 14-16 10-12

SEALED BUTT SPLICE CONNECTORS Butt splicing may be a necessary procedure for the replace- Strip 3/8 in. (9.5 mm) of insulation off the ends of the Compress the handles of the Packard Crimp Tool (HD- Refer to Table B-1. Since the size of the connectors var- ies with the gauge of the wire, always used the correct See Figure B-18. Determine the correct dye or nest for the crimping operation. Match the color or gauge wire marked on the butt splice connector with the correspond- Gently apply pressure to the handles until the crimper lightly secures one side of the metal insert inside the butt splice connector. The connector must be crimped in two See Fi

INSTALLATION ment of some components. the metal insert. sequence is complete. splice connector. along the length of the wires. tool attachment. appearance. Appendix B

38125-8) until the ratchet automatically opens. components when creating sealed splices. ing crimp cavity on the crimp tool. stages; one side then the other. exudes out both ends of the connector.

HOME 1. wires. 2. 3. 4. 5. 6. 7. 8. (00335a) 9. 10. B-12